Progressive stamping dies are a cornerstone in the manufacturing industry, crucial for efficiently producing intricate metal parts. These tools are essential for achieving high precision and productivity in metalworking.

Understanding this technology is vital for engineers, industry professionals, and potential buyers.

Progressive die stamping is a unique metal forming process used to create parts for various industries and applications.

This type of metal stamping incorporates multiple work stations, each performing different operations on the part, resulting in highly efficient and precise manufacturing.

A representative example of a product created using a progressive die is the lid of a beverage can. In this process, the pull tab is made in one progressive stamping operation, and the lid assembly is made in another.

The pull tab simultaneously feeds at a right angle into the lid assembly process. If you desire to know more about Progressive stamping die, now let’s delve deeper into the specifics of progressive stamping dies.

-

Table Of Contents

-

1. What is a Progressive Stamping Die?

-

2. Types of Die Stamping

-

3. What is the Difference Between Single Die and Progressive Die?

-

4. Difference Between Progressive Die, Compound Die, and Combination Die

-

5. Material Used in Progressive Stamping Dies

-

6. Progressive Die Stamping Machine and Design

-

7. Summary

Types of Die Stamping

Die stamping encompasses several methods, each suited to different applications and production requirements. The three main types are line, transfer, and progressive stamping.

1. Line Die Stamping: This method involves a series of individual dies arranged in a line, with the material moving from one die to the next.

Each die performs a specific operation. This method is flexible but less efficient than progressive stamping due to the need for multiple handling and alignment steps.

2. Transfer Die Stamping: In transfer die stamping, the material is transferred from one station to the next using mechanical transfer devices.

Each station performs a specific operation, and the material is precisely positioned for each step. This method is suitable for larger parts or when more complex forming is required.

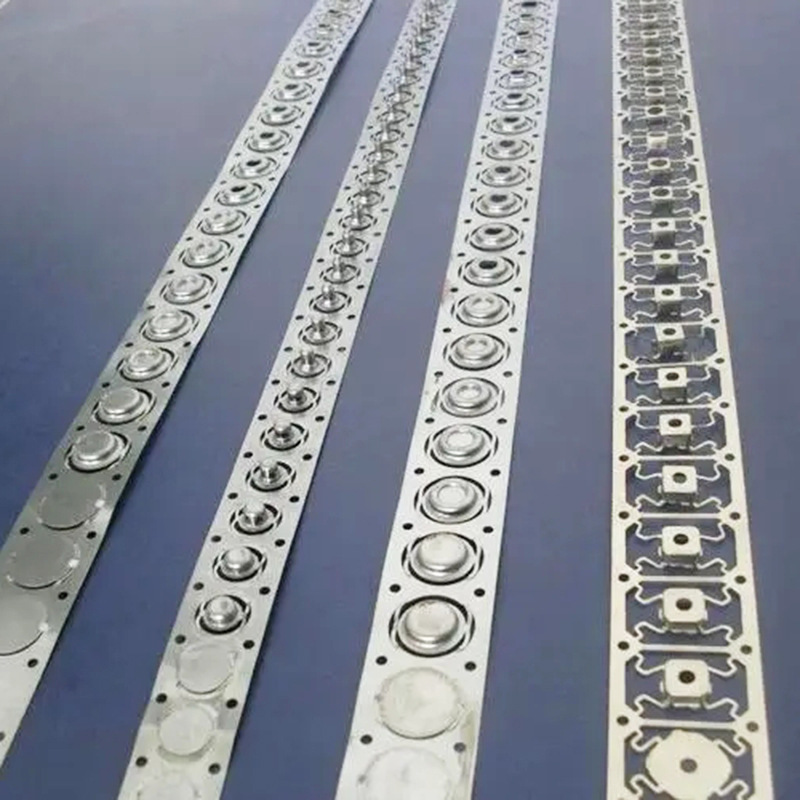

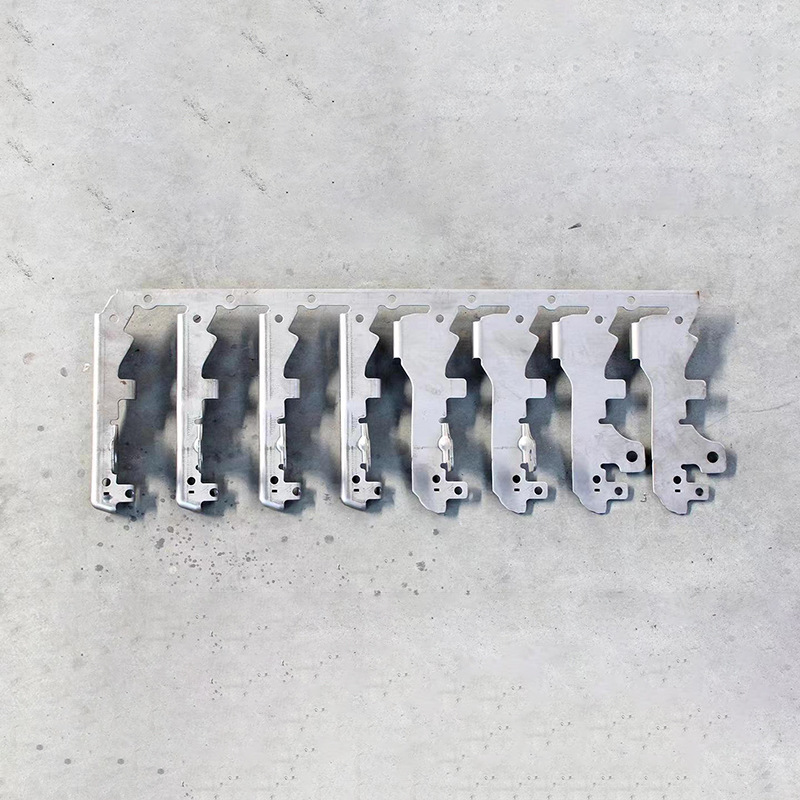

3. Progressive Die Stamping: Progressive die stamping is the most efficient method, especially for producing small to medium-sized parts in high volumes.

The material feeds continuously through the die, with each station performing a different operation. This method minimizes handling and maximizes throughput, making it ideal for large-scale production.

What is the Difference Between Single Die and Progressive Die?

Single dies and progressive dies serve different purposes in manufacturing. Single dies perform one operation at a time.

This simplicity makes them less expensive and easier to set up, but they are limited in their efficiency and productivity. They are suitable for low-volume production or when the part design is relatively simple.

In contrast, progressive dies are designed to perform multiple operations simultaneously within a single tool.

As the material feeds through the die, it undergoes a series of operations at different stations, such as cutting, bending, and punching. This integration of multiple steps into one continuous process makes progressive dies much more efficient and productive.

However, they are more complex and costly to design and manufacture, making them a better investment for high-volume production runs.

Difference Between Progressive Die, Compound Die, and Combination Die

Progressive dies, compound dies, and combination dies each have unique characteristics and applications.

1. Progressive Dies: These dies perform multiple operations in a sequence, with each stroke of the press advancing the material through different stations. This makes them ideal for producing complex parts that require several forming and cutting steps.

2. Compound Dies: Compound dies complete multiple operations in a single stroke of the press. This efficiency makes them suitable for high-volume production of simpler parts. However, they are less versatile than progressive dies for complex shapes.

3. Combination Dies: These dies combine features of both progressive and compound dies, allowing multiple operations to be performed both in sequence and simultaneously. This hybrid approach provides versatility and efficiency, making combination dies useful for a wide range of applications.

Material Used in Progressive Stamping Dies

Materials used in progressive stamping dies are chosen based on the specific requirements of the part being produced.

Common materials include various ferrous and nonferrous metals, each selected for its properties such as strength, ductility, and corrosion resistance.

1. Ferrous Metals: These include steel and its alloys, which are known for their strength and durability. Steel is commonly used in automotive and heavy machinery applications where structural integrity is critical.

2. Nonferrous Metals: These include aluminum, copper, and brass, which offer advantages such as lightweight, electrical conductivity, and resistance to corrosion. Nonferrous metals are often used in electronics, aerospace, and consumer goods.

Choosing the right material involves considering factors such as the mechanical properties required, the complexity of the part design, and the cost.

Materials must also be tested for their ductility and tensile strength to ensure they can withstand the stamping process without cracking or deforming.

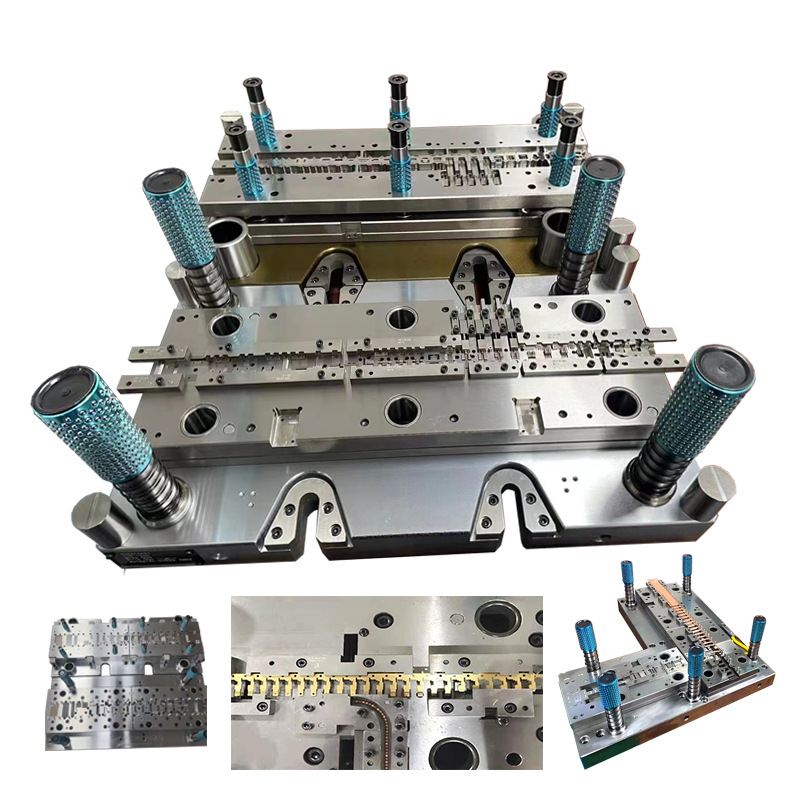

Progressive Die Stamping Machine and Design

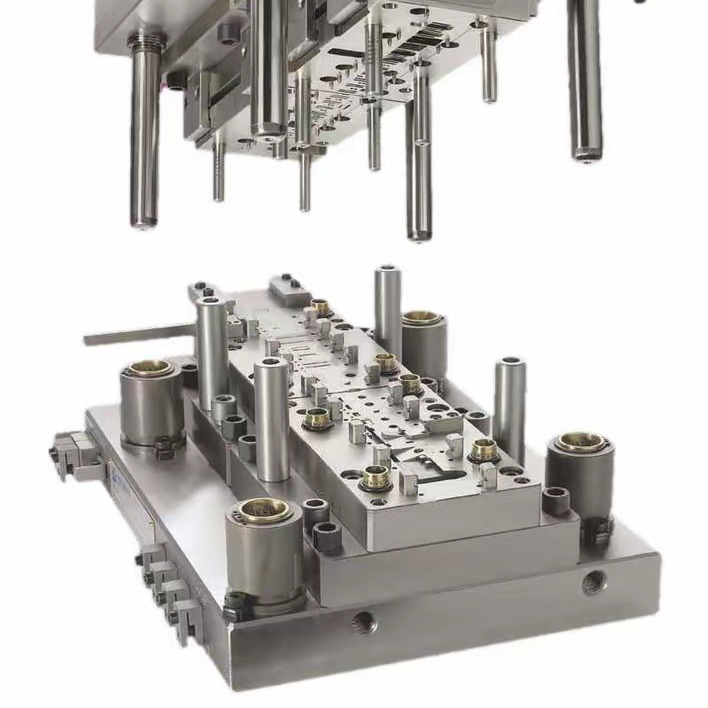

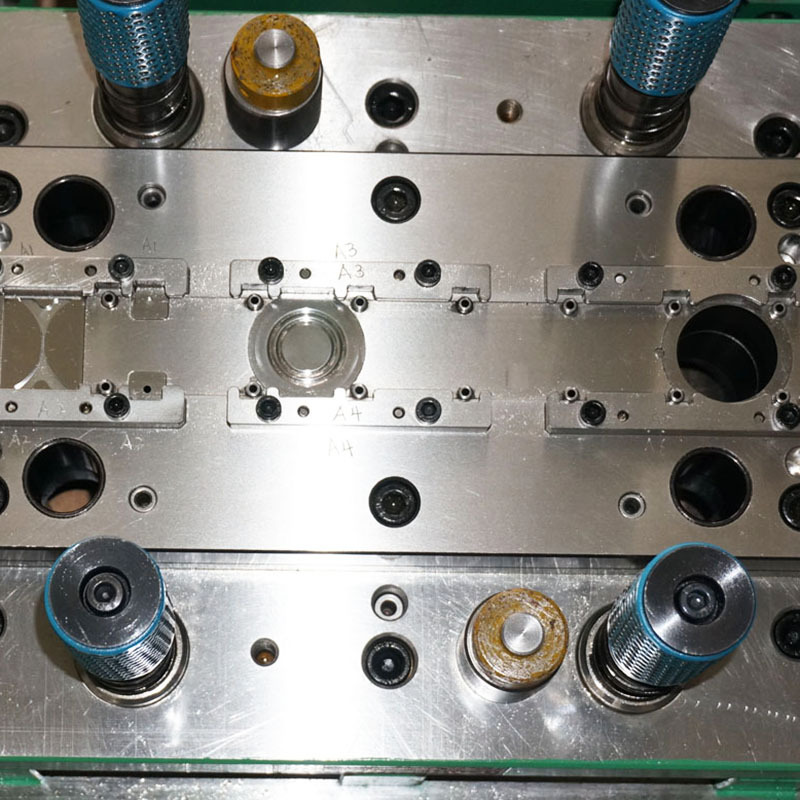

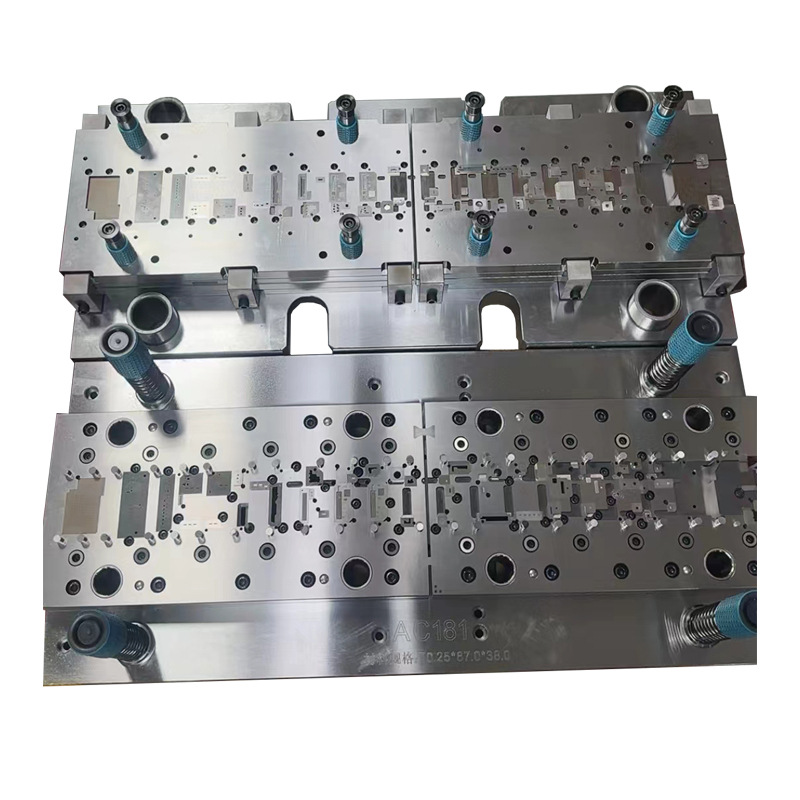

The design and operation of progressive die stamping machines are crucial for achieving efficient and high-quality production.

These machines incorporate various stations, each performing a specific task on the part, such as cutting, bending, and punching.

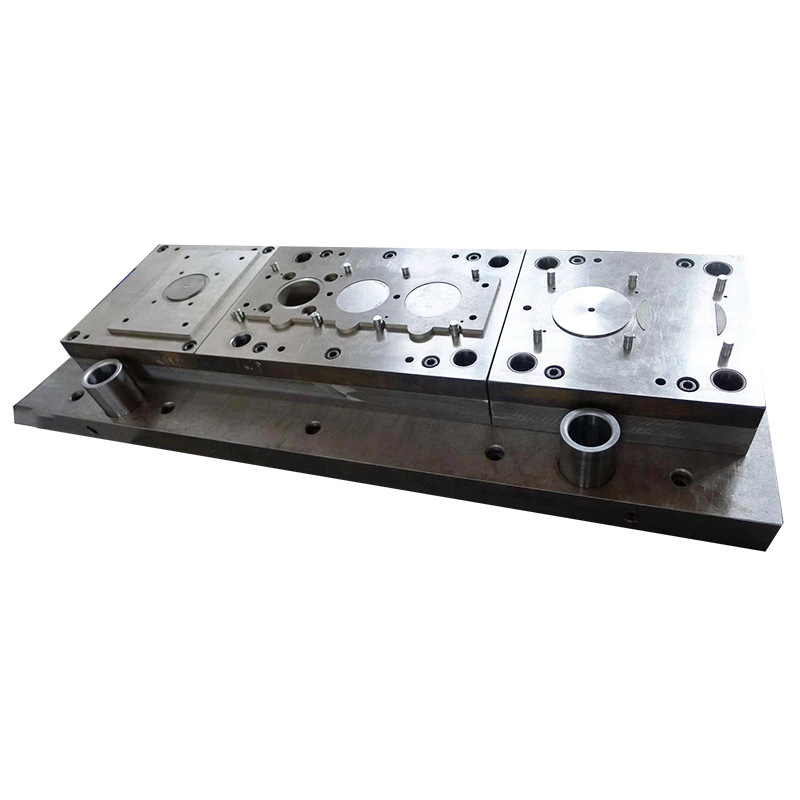

1. Machine Design: Progressive die stamping machines are designed to handle complex operations with high precision and speed. Key design considerations include the layout of the stations, the materials used for the dies, and the overall efficiency of the stamping process.

2. Material Handling: Efficient material handling is essential for maximizing throughput and minimizing waste. Progressive die stamping machines are equipped with automated feeders and conveyors to ensure continuous and precise feeding of the material through the die.

3. Maintenance and Calibration: Regular maintenance and calibration of the machines are essential for ensuring optimal performance and longevity. This includes inspecting and replacing worn components, lubricating moving parts, and calibrating the alignment and pressure of the dies.

4. Safety Features: Progressive die stamping machines are equipped with various safety features to protect operators and prevent accidents. These include guards, sensors, and emergency stop mechanisms that ensure safe operation and compliance with safety standards.

Summary:

Understanding progressive stamping dies is crucial for anyone involved in manufacturing. This article provides a clear overview of their applications, differences from other die types, and the materials used.

Progressive stamping dies offer significant advantages in terms of efficiency, precision, and versatility. By mastering these concepts, professionals can ensure efficient, high-quality production processes, ultimately leading to better products and satisfied customers.