In electronics and industrial design, protecting sensitive components from environmental damage is essential. Die cast aluminum enclosures provide a robust solution, combining durability, precision, and versatility.

As the demand for reliable and efficient enclosures grows, understanding the benefits and applications of die cast aluminum becomes essential.

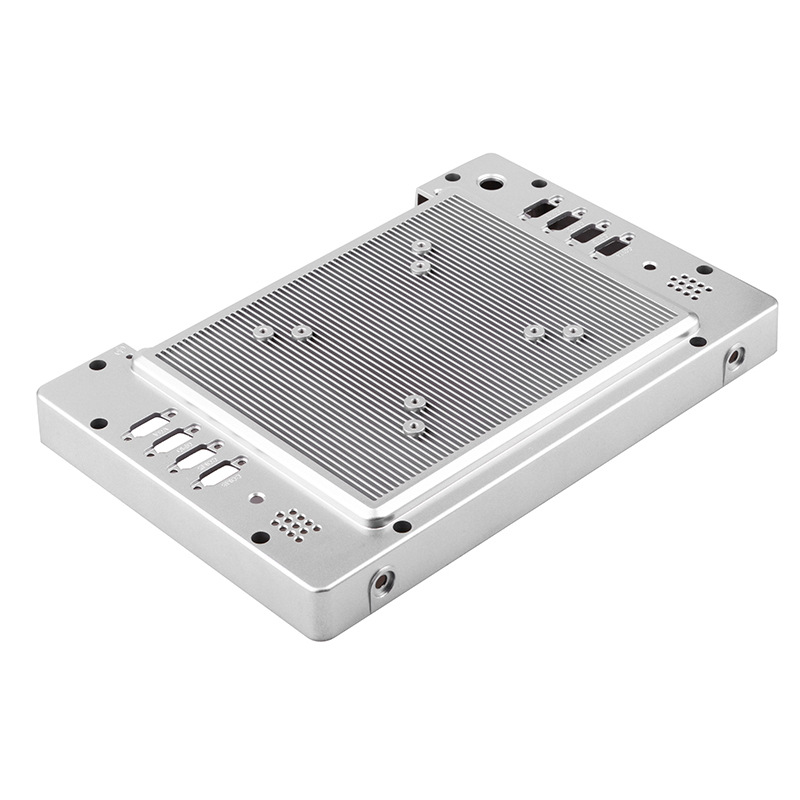

A die cast aluminum enclosure is a protective casing made by pouring molten aluminum into a mold, creating a specific shape.

These enclosures are commonly used to protect electronic components and other sensitive devices from external factors like dust, moisture, and electromagnetic interference.

Above is a brief definition and function of die a cast aluminum enclosure. If you want more information, let’s delve deeper into their benefits, manufacturing process, and why they are favored in various industries.

-

Table Of Contents

-

1. What is a Die Cast Aluminum Enclosure?

-

2. Benefits of Die Cast Aluminum Enclosures

-

3. How is Die Cast Aluminum Made?

-

4. Applications of Die Cast Aluminum Enclosures

-

5. Why Choose Aluminum for Enclosures?

-

6. Advantages of Die Cast Aluminum Enclosures

-

7. Custom Die Cast Aluminum Enclosures

-

8. Die Cast Aluminum vs. Plastic Enclosures

-

9. Summary

Benefits of Die Cast Aluminum Enclosures

Die cast aluminum enclosures offer numerous benefits that make them a preferred choice in many industries:

1. Durability: Aluminum is known for its strength and resilience, providing long-lasting protection for the enclosed components. Unlike plastic enclosures, which can crack or degrade over time, aluminum enclosures withstand harsh conditions and physical impacts.

2. Heat Dissipation: Aluminum’s excellent thermal conductivity helps dissipate heat generated by electronic components, preventing overheating. This is crucial for maintaining the performance and longevity of sensitive electronic devices.

3. Corrosion Resistance: Aluminum naturally resists corrosion, making it ideal for use in harsh environments. This property ensures that the enclosures remain intact and functional even when exposed to moisture, chemicals, or extreme weather conditions.

4. Lightweight: Aluminum is significantly lighter than other metals, reducing the overall weight of the final product. This is particularly advantageous in applications where weight is a critical factor, such as aerospace and automotive industries.

5. Precision: The die casting process allows for the creation of complex shapes with high precision, ensuring a perfect fit for components. This precision reduces the need for additional machining and post-processing, saving time and costs in the manufacturing process.

6. Aesthetic Appeal: Aluminum enclosures can be finished with various coatings and surface treatments, providing an attractive appearance and enhancing the overall aesthetic of the product.

How is Die Cast Aluminum Made?

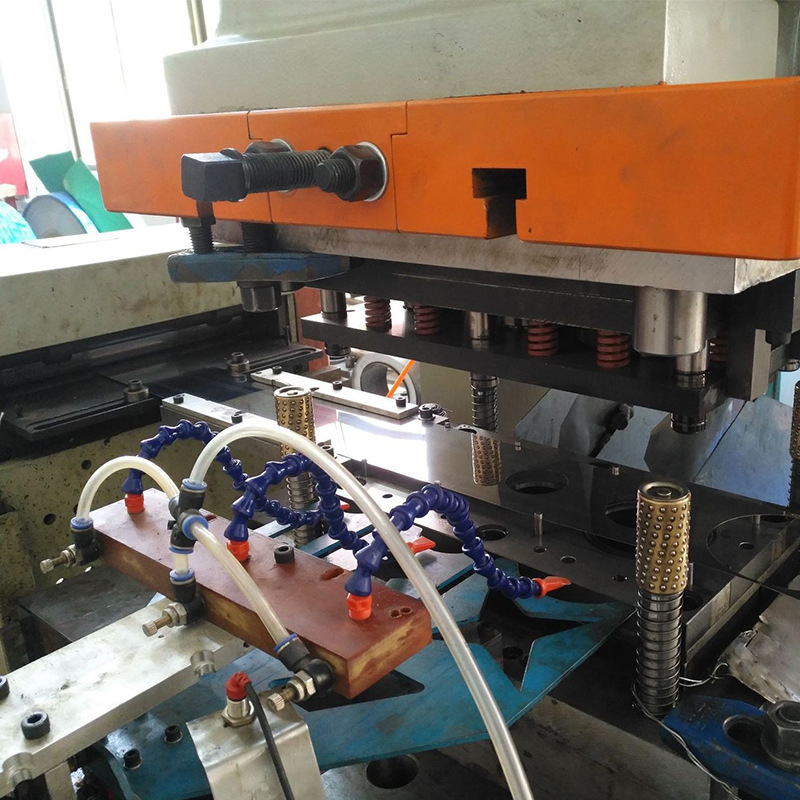

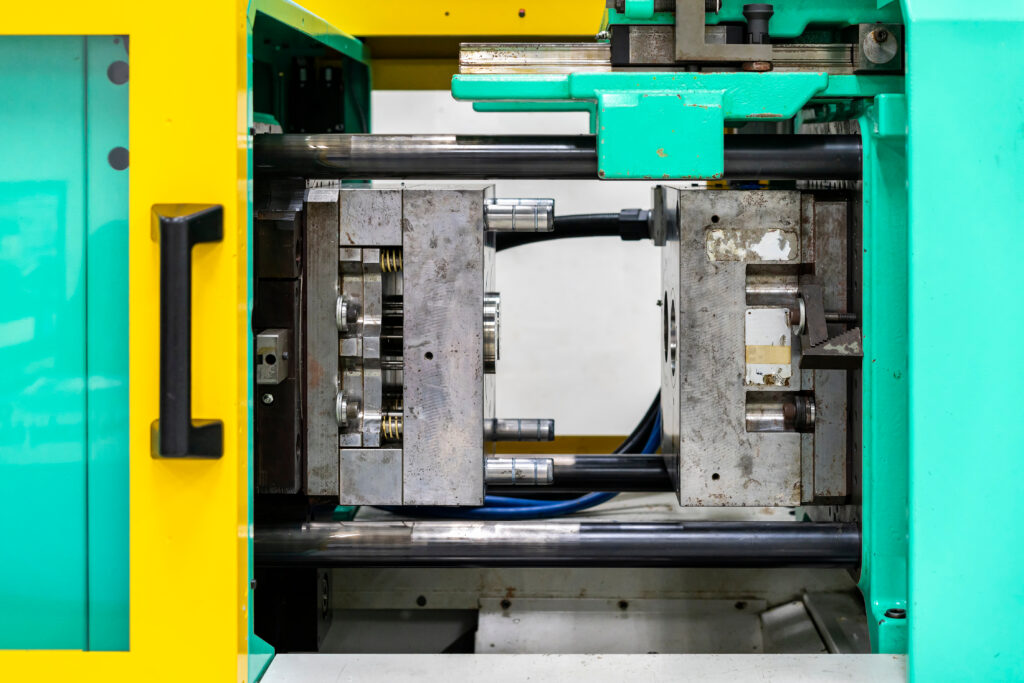

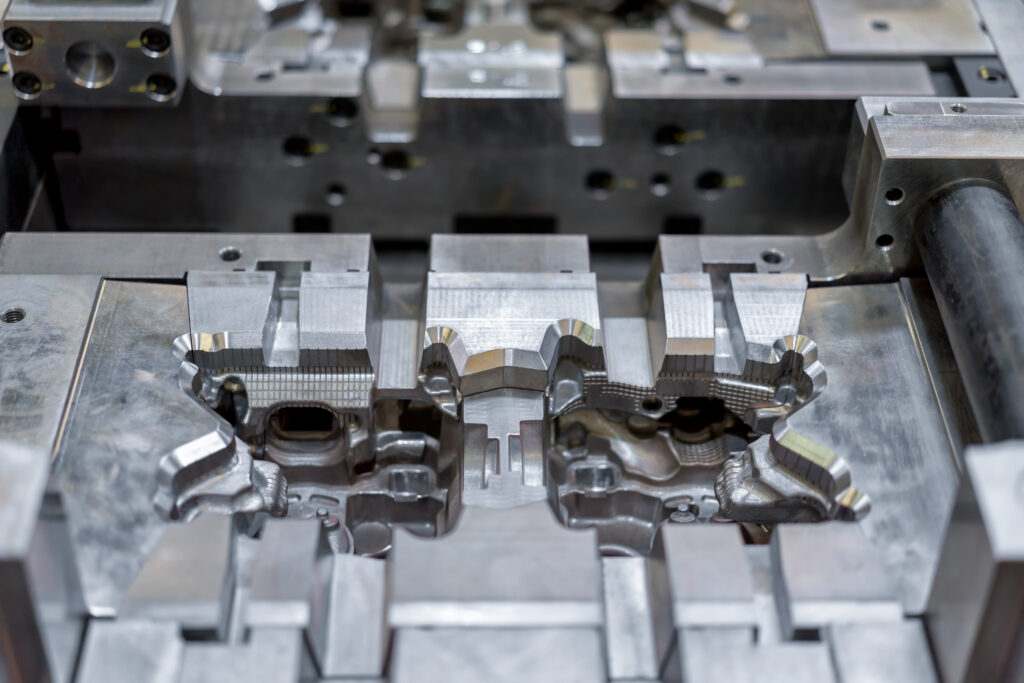

The die casting process involves several steps to produce high-quality aluminum enclosures:

1. Melting: Aluminum is heated until it becomes molten. The quality of the aluminum alloy used is critical, as it affects the final properties of the enclosure.

2. Injection: The molten aluminum is injected into a steel mold under high pressure. The mold is designed with the desired shape and dimensions of the enclosure.

3. Cooling: The aluminum is allowed to cool and solidify in the mold. This cooling process must be carefully controlled to prevent defects such as porosity or shrinkage.

4. Ejection: The solidified aluminum part is ejected from the mold, which is designed with ejector pins to facilitate the removal of the cast part.

5. Finishing: The part may undergo additional finishing processes, such as trimming, machining, and surface treatment. Trimming removes any excess material, while machining can refine dimensions or create additional features. Surface treatments, such as anodizing or painting, enhance the appearance and corrosion resistance of the enclosure.

Applications of Die Cast Aluminum Enclosures

Die cast aluminum enclosures are used in various applications across different industries:

1. Telecommunications: Protecting sensitive communication equipment from environmental hazards. Die cast aluminum enclosures shield components from electromagnetic interference and physical damage, ensuring reliable performance of communication systems.

2. Automotive Electronics: Housing electronic control units and other automotive electronics. The durability and heat dissipation properties of aluminum enclosures are essential for protecting components in the demanding environment of an automobile.

3. Medical Devices: Providing durable and reliable enclosures for medical instruments. Aluminum enclosures ensure that medical devices remain sterile and protected from contamination, enhancing patient safety and device reliability.

4. Industrial Machinery: Enclosing control systems and other sensitive components in industrial settings. These enclosures protect against dust, moisture, and mechanical impacts, ensuring the continuous and safe operation of industrial equipment.

5. Consumer Electronics: Enclosures for gadgets and devices such as smartphones, tablets, and wearable technology. The lightweight and aesthetic qualities of aluminum make it ideal for consumer products that require both functionality and a premium appearance.

6. Aerospace: Enclosures for avionics and other electronic systems in aircraft. The lightweight and durable properties of aluminum are critical for reducing weight and enhancing performance in aerospace applications.

7. Renewable Energy: Housing for components in solar panels, wind turbines, and other renewable energy systems. Aluminum enclosures protect sensitive electronics from harsh outdoor environments, ensuring the efficiency and longevity of renewable energy installations.

Why Choose Aluminum for Enclosures?

Aluminum is chosen for enclosures due to its unique combination of properties. Its lightweight nature makes it easy to handle and transport, while its strength ensures long-term protection. Here are some benefits of choosing aluminum for enclosures.

1. Thermal Management: Aluminum’s ability to conduct heat away from electronic components helps prevent overheating, which can lead to malfunctions or reduced lifespan.

2. Environmental Protection: Aluminum enclosures provide a robust barrier against environmental factors such as moisture, dust, and chemicals, which can damage sensitive electronics.

3. Cost-Effective Manufacturing: The die casting process for aluminum is efficient and cost-effective, allowing for the production of high-quality enclosures at a reasonable price.

4. Sustainability: Aluminum is a recyclable material, making it an environmentally friendly choice for enclosures. Recycling aluminum requires less energy than producing new aluminum, reducing the overall environmental impact.

Advantages of Die Cast Aluminum Enclosures

Compared to other materials, die cast aluminum enclosures offer several advantages:

1. Mechanical Strength: Aluminum enclosures provide superior mechanical strength compared to plastic enclosures. They can withstand higher levels of physical impact and stress, making them suitable for demanding applications.

2. Temperature Resistance: Aluminum maintains its structural integrity at higher temperatures, whereas plastic enclosures may deform or melt under similar conditions.

3. EMI Shielding: Aluminum enclosures provide excellent shielding against electromagnetic interference (EMI), protecting electronic components from external electromagnetic fields.

4. Customizability: The die casting process allows for the production of custom designs, enabling manufacturers to create enclosures that meet specific requirements and integrate seamlessly with other components.

5. Longevity: The durability and corrosion resistance of aluminum ensure that enclosures have a long service life, reducing the need for frequent replacements and maintenance.

Custom Die Cast Aluminum Enclosures

Manufacturers often offer custom die cast aluminum enclosures tailored to specific requirements. This allows for unique designs that meet the exact needs of the application, ensuring optimal performance and protection.

1. Design Flexibility: Custom die cast aluminum enclosures can be designed to accommodate complex geometries and intricate details, providing a perfect fit for specific components.

2. Enhanced Features: Customization allows for the inclusion of features such as mounting holes, heat sinks, and cable entries, enhancing the functionality and ease of installation.

3. Branding: Custom enclosures can be designed with logos, branding, and specific color schemes, aligning with the company’s brand identity.

4. Prototyping and Testing: Manufacturers can produce prototypes of custom enclosures for testing and validation, ensuring that the final product meets all performance and quality standards.

Die Cast Aluminum vs. Plastic Enclosures

While plastic enclosures are also popular, die cast aluminum enclosures provide superior strength, durability, and heat dissipation. Aluminum enclosures are better suited for harsh environments and applications where mechanical strength is crucial.

1. Strength and Durability: Aluminum enclosures are more robust and resistant to physical impacts compared to plastic enclosures. They are less likely to crack or deform under stress.

2. Heat Dissipation: Aluminum’s thermal conductivity is far superior to that of plastic, making it better suited for applications where heat dissipation is critical.

3. Environmental Resistance: Aluminum enclosures offer better resistance to UV radiation, chemicals, and extreme temperatures, making them more suitable for outdoor and industrial applications.

4. Aesthetic Appeal: Aluminum enclosures can be finished with various coatings, providing a high-quality appearance that is often more visually appealing than plastic.

5. Cost Considerations: While plastic enclosures may be cheaper to produce in small quantities, the cost-effectiveness of aluminum die casting increases with larger production volumes due to the efficiency of the process.

Summary:

Die cast aluminum enclosures are essential in many industries for protecting sensitive electronic components. Their durability, precision, and versatility make them a preferred choice for engineers and buyers alike.

Understanding the benefits, applications, and manufacturing process of these enclosures highlights their importance in modern electronics and industrial design. Whether for custom applications or mass-produced products, the value of die cast aluminum enclosures is unmatched.