Aluminum extrusion is a critical process in the manufacturing industry, enabling the creation of complex profiles with high precision. Understanding this process is essential for us to leverage its benefits.

Briefly speaking, aluminum extrusion involves heating an aluminum billet and forcing it through a die to create a specific cross-sectional shape.

The process includes preparing the die, preheating the billet, and using a press to extrude the material, resulting in durable and versatile aluminum profiles.

This article provides an in-depth look at the aluminum extrusion process, the factors we should concern, and its common mistakes, helping us make informed decisions.

Now, let’s delve into the detailed steps involved in the aluminum extrusion process.

What are the Main Steps in the Aluminum Extrusion Process?

The aluminum extrusion process can be broken down into several key steps:

1. Die Preparation: The process begins with the preparation of the extrusion die. The die, designed by advanced software, is aimed to create the specific cross-sectional profile required for the final product. It is usually made of hardened steel and must be carefully crafted to ensure accuracy and durability. The design of the die is critical as it determines the shape of the extruded aluminum.

2. Preheating the Aluminum Billet: An aluminum billet is a solid block of aluminum alloy. Before extrusion, the billet is preheated to a temperature between 700°F and 930°F (375°C to 500°C), depending on the alloy. This heating process softens the billet, making it easier to extrude through the die. The preheating process also helps to ensure uniformity in the material, reducing the risk of defects and improving the quality of the final product.

3. Transferring the Billet to the Extrusion Press: Once preheated, the billet is transferred to the extrusion press. This machine exerts significant force to push the billet through the die. The pressure can reach up to 15,000 tons, depending on the complexity and size of the profile being extruded.

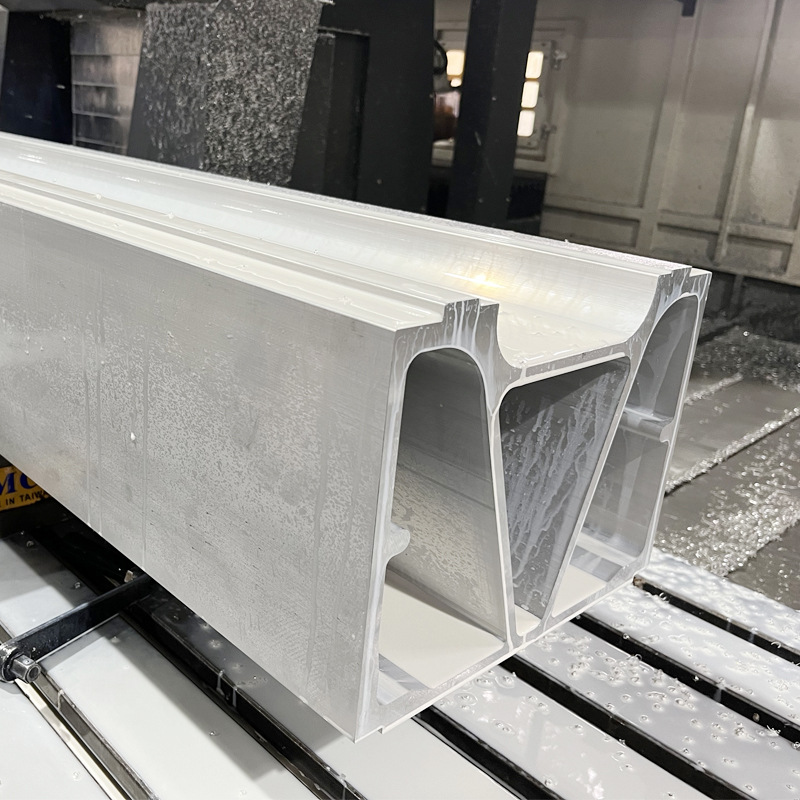

4. Extrusion Through the Die: The softened billet is forced through the die by a ram. As the aluminum passes through the die, it takes on the shape of the die’s opening. The extruded aluminum emerges from the other side of the die as a continuous profile with the desired cross-sectional shape. This step is the heart of the extrusion process, where the transformation from billet to profile occurs.

5. Cooling and Stretching: After extrusion, the aluminum profile is cooled using air or water quenching. This cooling process helps to solidify the shape and improve the material’s strength. The profile is then stretched to straighten any distortions caused during extrusion. Cooling is a critical step that must be managed carefully to avoid thermal stresses that can lead to warping or other defects. Stretching helps to align the metal’s grain structure, enhancing the mechanical properties and ensuring dimensional accuracy of the final product.

6. Cutting to Length: Once cooled and straightened, the extruded profiles are cut to the desired lengths. These lengths can vary based on the application and customer requirements. Cutting is typically done using saws or shears designed to handle aluminum, ensuring clean and precise cuts.

7. Heat Treatment: Some aluminum extrusions undergo additional heat treatment processes to enhance their mechanical properties. These treatments can improve strength, hardness, and other characteristics essential for specific applications. Common heat treatment processes include aging and annealing.

8. Finishing: The final step involves applying any necessary finishes to the extruded profiles. This can include anodizing, painting, or other surface treatments to enhance appearance and corrosion resistance. Anodizing is an electrochemical process that increases the thickness of the natural oxide layer on the surface of aluminum, improving its durability and aesthetic appeal.

What Should We Consider in the Process of Aluminum Extrusion?

Although aluminum extrusion is a relatively common technique in manufacturing, there are several key factors we need to consider avoiding making mistakes, ensuring the products high-quality.

1. Material Selection: Choose the right aluminum alloy that suits the intended application, considering factors like strength, corrosion resistance, and conductivity.

2. Die Design: Ensure that the die is designed precisely for the desired profile, considering factors like the complexity of the shape and the tolerances required.

3. Temperature Control: Maintain appropriate temperature settings throughout the process to ensure smooth extrusion and avoid defects.

4. Speed and Pressure: Optimize the speed and pressure of the extrusion press to balance between productivity and quality.

5. Surface Finish: Consider post-extrusion treatments such as anodizing or painting to enhance the appearance and performance of the final product.

6. Quality Control: Implement thorough inspection and testing to ensure that the extruded profiles meet specifications and quality standards.

What are Common Mistakes in the Process of Aluminum Extrusion?

1. Inadequate Die Maintenance: Neglecting regular maintenance of dies can lead to poor-quality extrusions and increased production downtime.

2. Incorrect Alloy Selection: Using an inappropriate alloy can result in mechanical failure or corrosion, impacting the product’s performance.

3. Improper Temperature Settings: Failing to control the temperature correctly can cause defects like surface cracking or uneven profiles.

4. Excessive Extrusion Speed: Pushing the material through too quickly can lead to surface imperfections and structural weaknesses.

5. Ignoring Tolerances: Overlooking dimensional tolerances during design and production can result in parts that do not fit or function as intended.

Summary:

Understanding the aluminum extrusion process is crucial for making informed decisions in manufacturing and purchasing.

This versatile and efficient process enables the creation of complex and durable profiles used in various industries.

By exploring the process, considerations and common mistakes of aluminum extrusions, we can ensure the quality and performance of extruded aluminum products, ultimately driving success in the projects and operations.