In the realm of manufacturing, metal stamping dies play a crucial role in shaping and cutting metal sheets into specific designs.

Selecting the right material for these dies is vital for efficiency and product quality. The choice of material affects the die’s durability, performance, and the overall cost of production.

Actually, metal stamping dies are typically made from materials that offer high hardness, strength, and wear resistance to withstand the pressures and forces involved in the stamping process. The most common materials include steel, carbide, aluminum bronze, etc.

In this article, we will explore the various materials used for metal stamping dies and their benefits to provide a detailed information, ensuring a better manufacturing result.

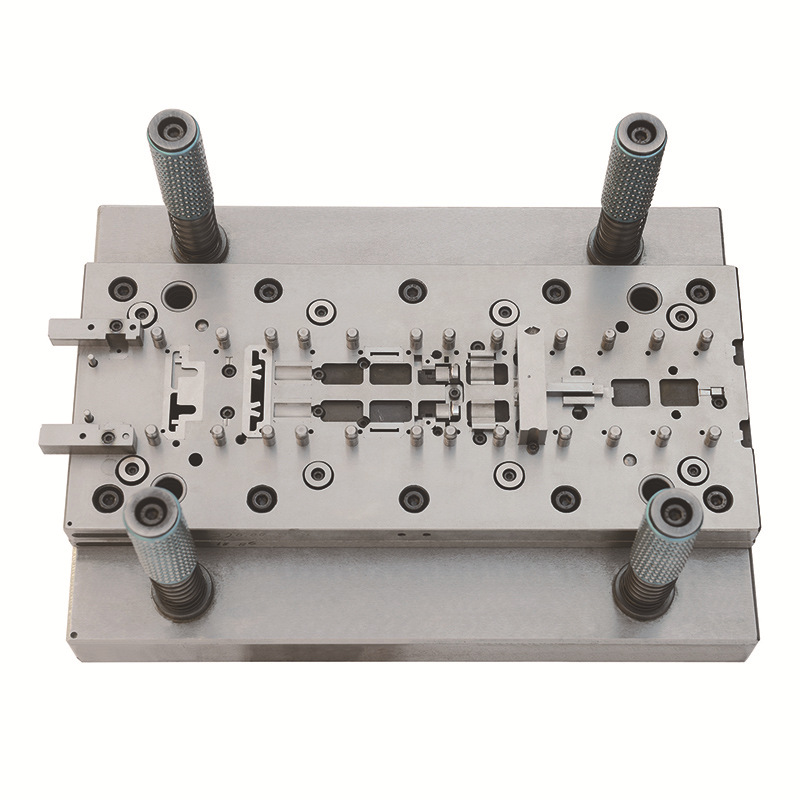

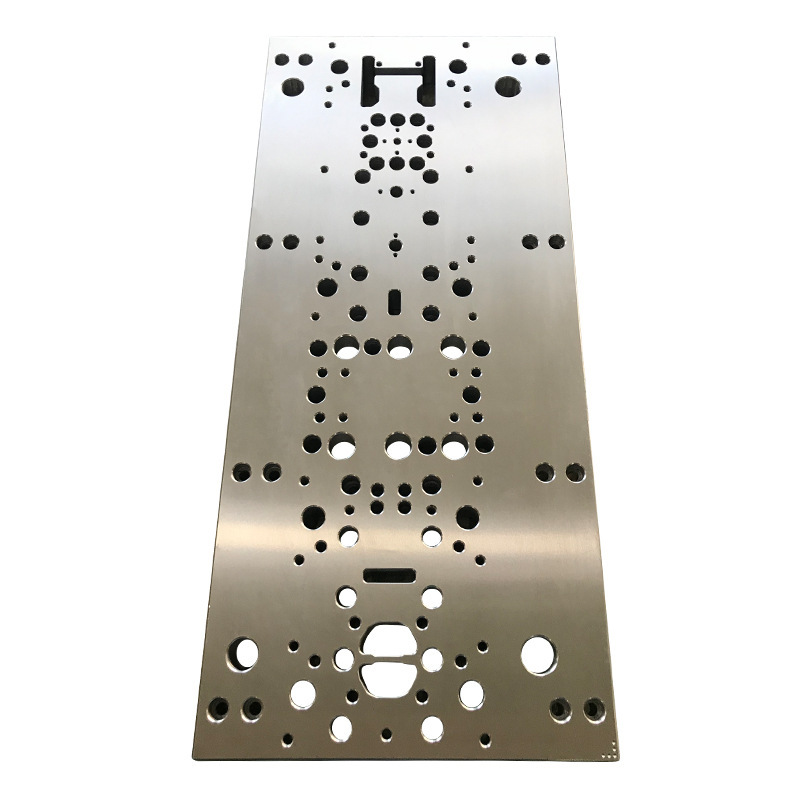

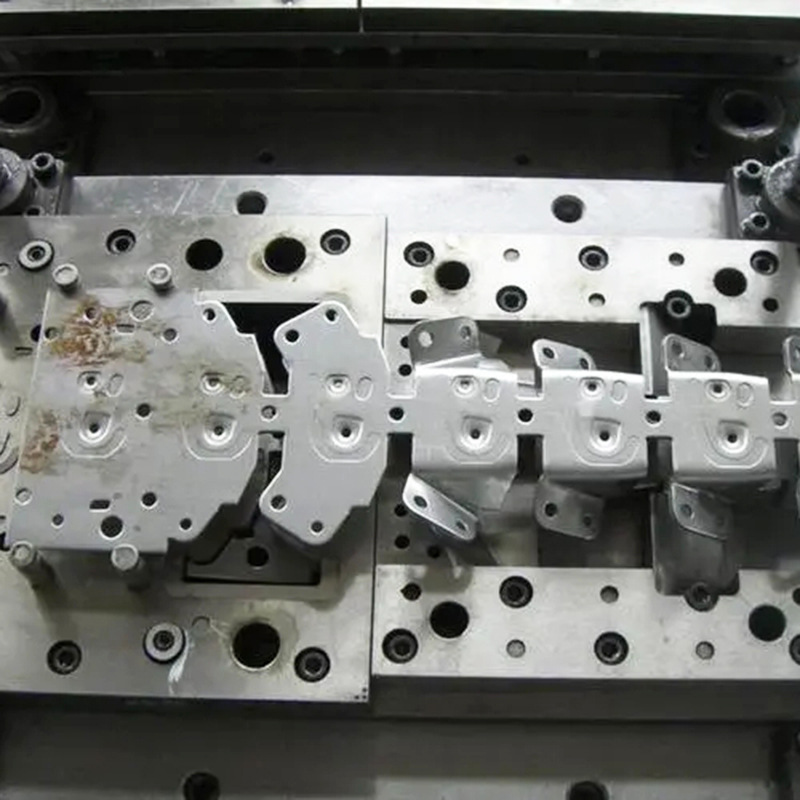

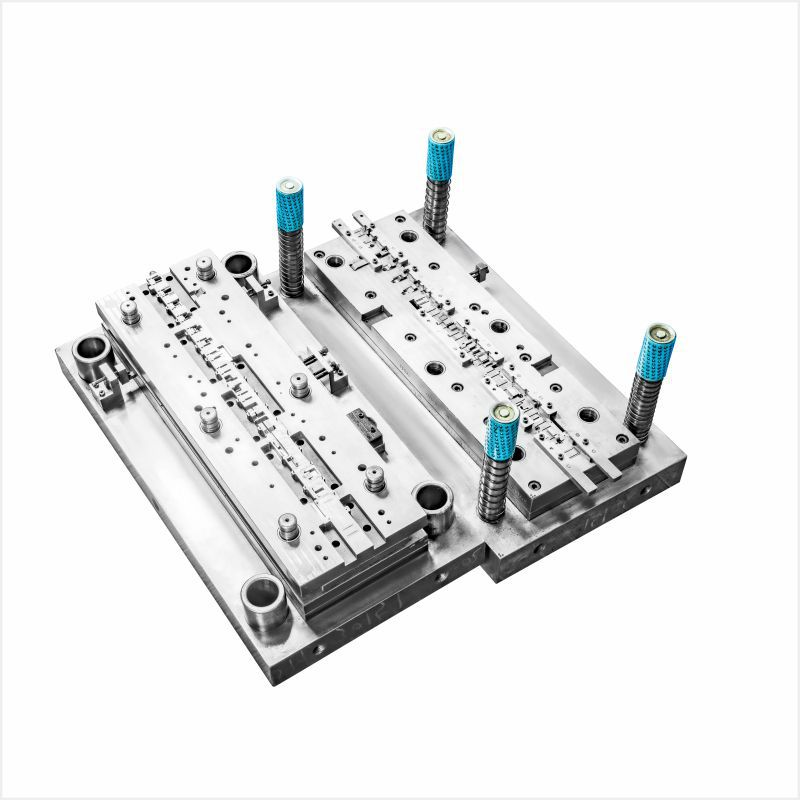

What Are the Components of a Metal Stamping Die?

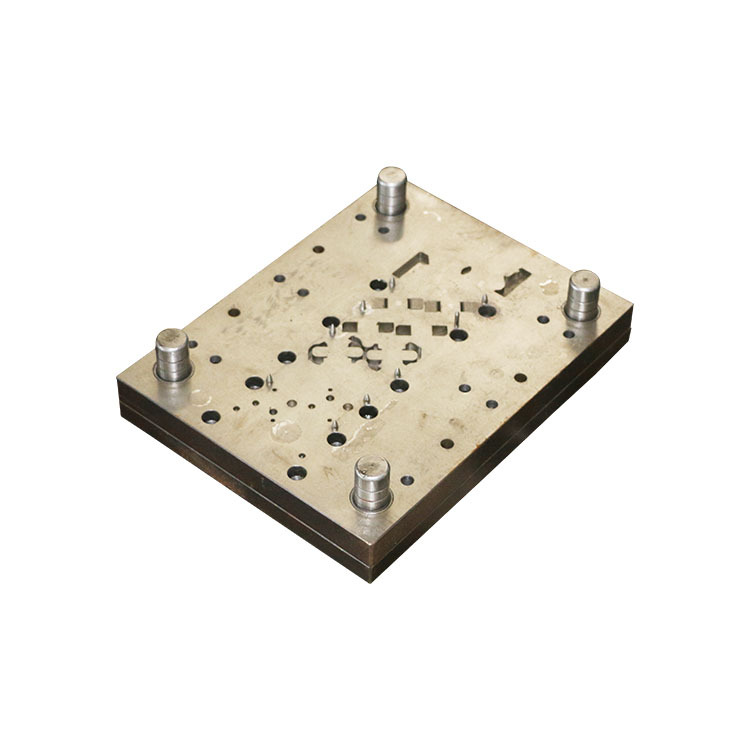

A metal stamping die comprises several key components that work together to ensure precise and efficient metal forming. Understanding these components helps in appreciating the complexity and engineering involved in die making.

• Die Plates (Shoes, Sets): These serve as the foundation where other die tools and components are mounted. They provide the necessary support and stability to the die assembly, ensuring that all components function correctly.

• Die Guide Pins and Bushings: These components ensure alignment and precision during the stamping process. Guide pins and bushings work together to keep the die components in the correct position, reducing the risk of misalignment and ensuring consistent results.

• Die Punches and Buttons: These elements perform the actual cutting and shaping of the metal. Die punches are responsible for creating the desired shapes, while die buttons support the punches and ensure clean cuts.

• Die Springs and Retainers: These parts help in maintaining the necessary tension and positioning of the die components. Springs provide the force needed to return the die components to their original position after each stroke, while retainers hold everything in place.

What are the Best Materials for Metal Stamping Dies?

The best material for stamping a die typically includes a combination of materials known for their strength, durability, and resistance to wear.

The choice of material depends on the specific requirements of the stamping process, including the type of metal being stamped and the production volume. The most common materials used for metal stamping dies include:

• Steel: Widely used due to its strength and durability, steel is a versatile material that can be tailored to meet various needs. Different grades of steel, such as tool steel and high-speed steel, offer specific properties suitable for different applications.

• Carbide: Known for its exceptional hardness and wear resistance, carbide is used in high-precision applications where maintaining sharp edges is critical. Carbide dies are often used in high-volume production where the die must withstand significant wear and tear.

• Hard Alloy: Known for its toughness and resistance to wear, hard alloy is ideal for high-volume production where the die is subjected to continuous use. Its ability to maintain sharp edges and resist deformation makes it a preferred choice for precision stamping.

• Steel Bonded Hard Alloy: Combines the benefits of steel and hard alloy for enhanced performance. This material offers a balance between toughness and hardness, making it suitable for a wide range of applications.

• Zinc Base Alloy: Used for specific applications requiring low melting points, zinc base alloys are easy to cast and provide good wear resistance. They are often used in situations where cost-effectiveness and ease of manufacturing are important.

• Copper Alloys: Used for their excellent conductivity and corrosion resistance, copper alloys are ideal for electrical components and other applications where these properties are important. The versatility of copper alloys makes them suitable for a wide range of stamping applications.

• Aluminum Bronze: Offers good wear resistance and durability, making it suitable for applications where corrosion resistance is also a consideration. Aluminum bronze is often used in environments where the die is exposed to harsh conditions.

What are the Benefits of Different Materials in Metal Stamping Dies?

Each material used in metal stamping dies offers unique benefits that contribute to the overall efficiency and quality of the stamping process. By understanding these benefits, manufacturers can select the best material for their specific needs.

• Strength and Durability: Ensures the die can handle high-volume production without deforming. Materials like tool steel and high-speed steel are known for their strength and ability to maintain their shape under stress.

• Wear Resistance: Extends the lifespan of the die, reducing the need for frequent replacements. Materials like carbide and hard alloy offer exceptional wear resistance, making them ideal for high-volume production where the die is subjected to continuous use.

• Precision: Maintains the accuracy of the stamped parts, ensuring consistent quality. Materials like tool steel and carbide retain their sharp edges and precision, allowing for the production of intricate and precise components.

• Corrosion Resistance: Important for applications where the die is exposed to harsh environments. Materials like aluminum bronze and copper alloys offer good corrosion resistance, ensuring the longevity of the die in challenging conditions.

• Cost-Effectiveness: Some materials offer a balance between performance and cost, making them suitable for applications where budget considerations are important. Zinc base alloys, for example, provide good wear resistance at a lower cost compared to other materials.

Summary:

Choosing the right material for a metal stamping die is essential for ensuring the efficiency and quality of the manufacturing process.

By understanding the different materials and their benefits, industry professionals can make informed decisions that enhance production and product longevity.

Whether it’s the strength and durability of tool steel, the wear resistance of carbide, or the versatility of copper alloys, selecting the appropriate material for metal stamping dies is a critical factor in achieving optimal performance and cost-effectiveness in manufacturing operations.