In today’s fast-paced and technologically advanced world, high precision metal stamping plays a crucial role in various industries. From automotive to aerospace, the need for components with exact specifications and superior quality has never been greater.

Generally speaking, high precision metal stamping involves using high tonnage presses and specialized dies to create intricate metal parts with tight tolerances.

When choosing suppliers, there are key factors we need to consider: experience, quality control, turnaround time, customer service, technology and equipment, which can help us screen out the most suitable suppliers for us.

Having been deeply involved in this field for many years, I will now introduce in detail what High Precision Metal Stamping Parts are and how to choose the best supplier, which are the most important concern for customers.

-

Table Of Contents

-

1. What Are High Precision Metal Stamping Parts and How to Choose the Best Supplier?

-

2. High Precision Metal Stamping Parts for All Needs

-

3. What is the Best Metal for Metal Stamping?

-

4. Benefits of High Precision Metal Stamping

-

5. How to Choose the Best Supplier for Metal Stamping Parts

-

6. Summary

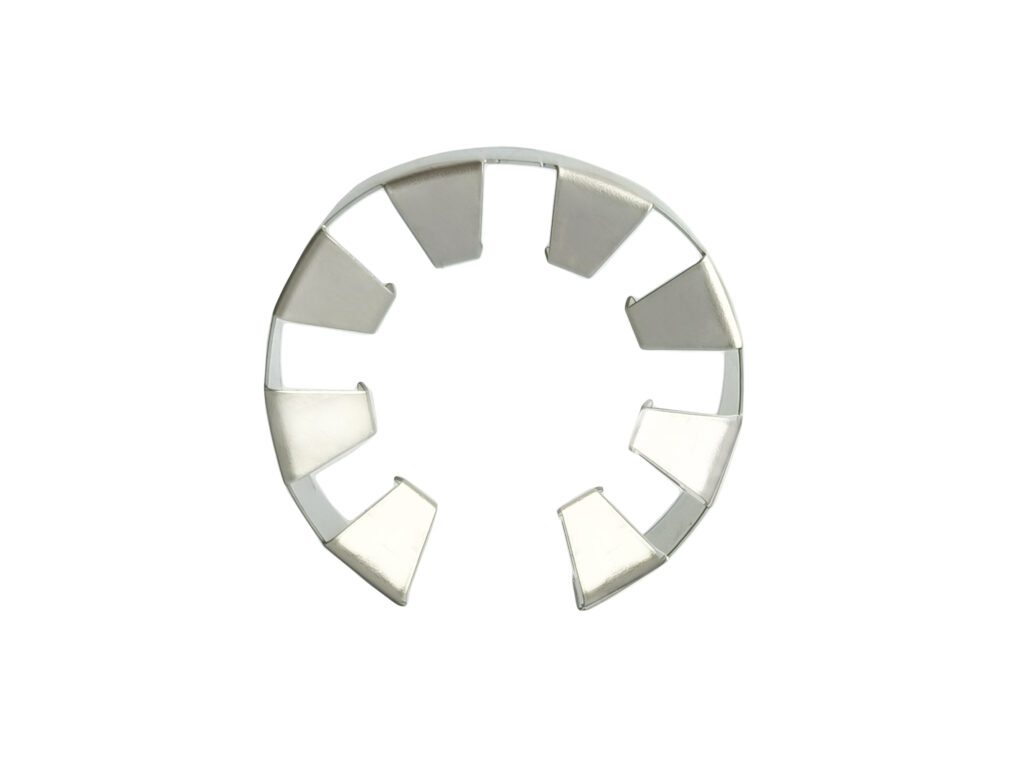

High Precision Metal Stamping Parts for All Needs

Metal stamping is a manufacturing process that involves converting flat metal sheets into specific shapes.

This is achieved through a combination of punching, blanking, bending, and other techniques. The process utilizes dies and stamping presses to shape the metal accurately.

The precision in this process reduces material waste, lowers costs, and increases production speeds, which is beneficial for both manufacturers and end-users.

What is the Best Metal for Metal Stamping?

The four major types of metal stamping are progressive die stamping, four-slide stamping, deep draw stamping, and custom metal stamping, each with unique applications and benefits:

• Progressive Die Stamping: It involves a series of stations, each performing a specific operation on the metal. This method is highly efficient and suitable for producing large quantities of parts.

• Four-slide Stamping: Known for its versatility, this method can create complex parts in a single operation. Four-slide machines use four horizontal slides to shape the metal, allowing for intricate bends and twists. This process is particularly useful for producing parts with complex geometries and multiple bends.

• Deep Draw Stamping: Used for creating deep, hollow shapes, this method is ideal for parts that require significant depth. This process is commonly used for making components such as cans, cups, and automotive parts.

Benefits of High Precision Metal Stamping

High precision metal stamping offers numerous benefits, making it an ideal manufacturing process for various industries. Some of the key benefits include:

• Cost-Effectiveness: It is a cost-effective manufacturing method, particularly for high-volume production runs. The ability to produce large quantities of parts quickly and accurately reduces overall production costs.

• Quality and Accuracy: Precision stamping ensures that each part meets exact specifications, resulting in high-quality components with consistent performance.

• Versatility: The ability to work with a wide range of materials and produce complex shapes makes precision stamping a versatile manufacturing process suitable for various applications.

• Scalability: Precision stamping is ideal for both low and high-volume production, making it a scalable solution for manufacturers of all sizes.

• Reduced Lead Times: The automation and high-speed capabilities of stamping machines reduce lead times, allowing for faster production and delivery of parts.

How to Choose the Best Supplier for Metal Stamping Parts

Selecting the right supplier for your metal stamping needs is crucial to ensure high-quality results. There are some key factors to consider:

• Experience and Expertise: Look for suppliers with a proven track record in producing high precision metal stamping parts. Experienced suppliers are more likely to have the expertise and capabilities needed to meet your specific requirements.

• Quality Control: Ensure the supplier has stringent quality control measures in place to guarantee the accuracy and consistency of their parts. This includes regular inspections, testing, and certifications to ensure the highest quality standards are met.

• Turnaround Time: Consider the supplier’s ability to deliver parts within your required timeframe. Reliable suppliers should be able to provide accurate lead times and meet your deadlines consistently.

• Customer Service: Look for suppliers that offer excellent customer service and support. This includes clear communication, responsiveness, and a commitment to meeting your needs and expectations.

• Technology and Equipment: Ensure the supplier uses advanced technology and equipment to produce high-quality parts. This includes state-of-the-art stamping machines, precision tooling, and automated processes that enhance efficiency and accuracy.

Summary

High precision metal stamping parts are crucial for many industries, offering numerous benefits such as cost-efficiency, high quality, and versatility. By understanding the different types of metal stamping and the best materials to use, you can make informed decisions when selecting a supplier.

Ensure you choose a reliable partner with the experience, capabilities, and commitment to quality needed to meet your specific requirements and achieve the highest quality results. With the right supplier, you can take full advantage of the benefits of precision metal stamping and enhance the performance and reliability of your products.