Skiving heat sinks are an essential component in thermal management, used to dissipate heat in various electronic applications. Understanding the intricacies of skiving heat sinks can help engineers and production managers make informed decisions.

Skiving heat sinks are manufactured through a precise process where thin slices of material, usually copper or aluminum, are shaved from a larger block to form fins.

These fins significantly enhance the surface area for heat dissipation, making skiving heat sinks highly efficient for cooling electronic components.

Let’s delve deeper into the world of skiving heat sinks and explore their various aspects.

-

Table Of Contents

-

1. Everything You Need to Know About Skiving Heat Sinks

-

2. What Are Skiving Heat Sinks?

-

3. What Are the Steps of the Skiving Heat Sinks Production?

-

4. What is the Equipment Used in Skiving Heat Sinks?

-

5. What Are the Applications of Skiving Heat Sinks?

-

6. What Are the Benefits and Limitations of Skiving Heat Sinks?

-

7. How Much Do Skiving Heat Sinks Cost?

-

8. What Kind of Material Can Be Used in Skiving Heat Sinks?

-

9. Summary

What Are Skiving Heat Sinks?

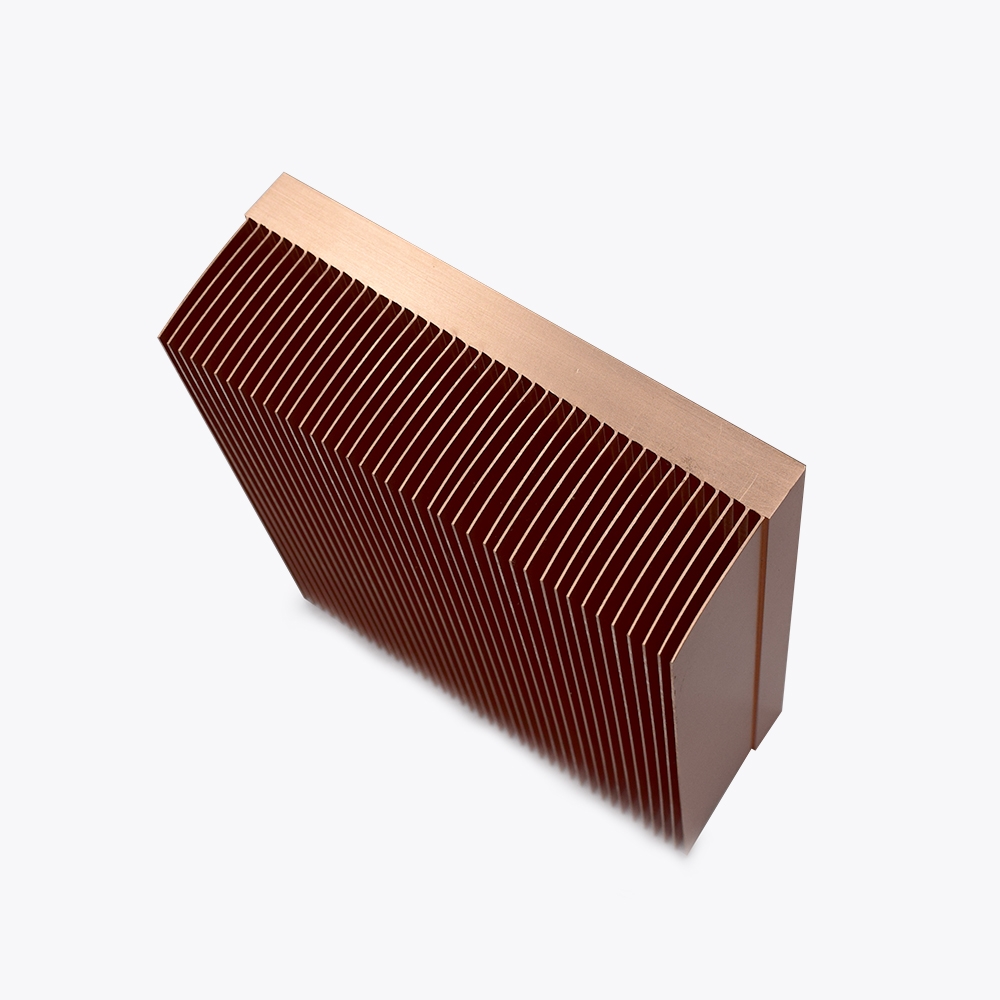

Skiving heat sinks are produced by slicing thin layers from a metal block, forming fins that significantly enhance thermal performance by increasing surface area.

This method is often used with copper and aluminum, materials known for their excellent thermal conductivity. The fins created through skiving are integral to the base, ensuring efficient heat transfer and structural stability.

Skiving heat sinks operate on the principle of maximizing surface area to improve heat dissipation. Heat sinks are critical in preventing overheating in electronic components, which can lead to malfunction or reduced lifespan.

By increasing the surface area, skiving heat sinks allow for more efficient thermal exchange with the surrounding environment. This process is particularly beneficial in high-power applications where traditional cooling methods might fall short.

What Are the Steps of the Skiving Heat Sinks Production?

1. Material Preparation: involves selecting the right metal block, usually copper or aluminum, ensuring it is free from impurities, and cutting it to the appropriate size for the skiving process. The metal block must be uniform in density to prevent irregularities in the fins.

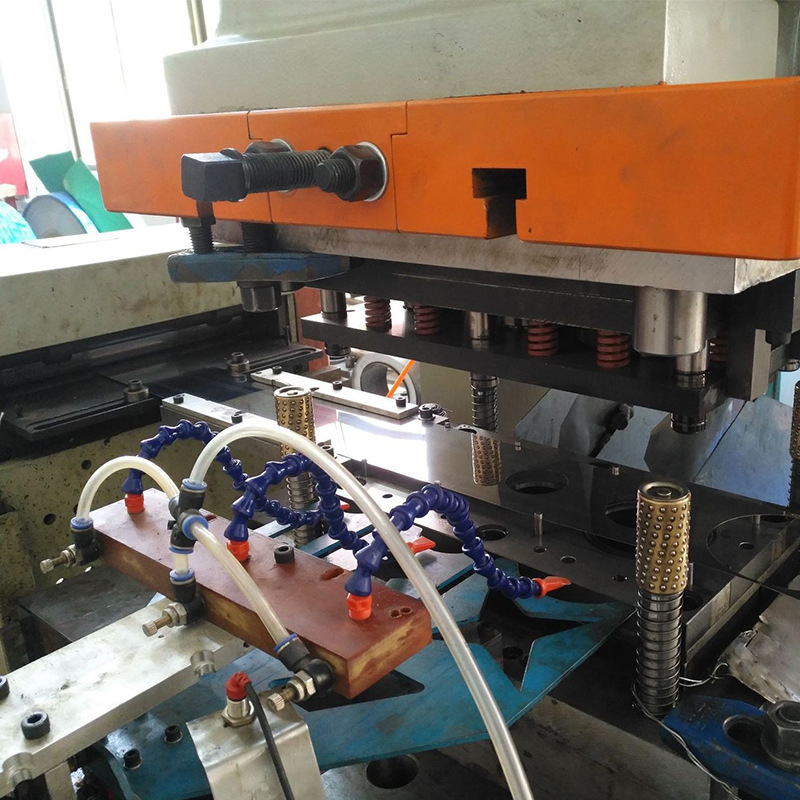

2. Skiving: Thin layers of the material are sliced off to form fins. This is done using a precision skiving machine. The machine’s blades must be exceptionally sharp and well-maintained to achieve the desired thinness and uniformity.

3. Shaping and Aligning: The fins are then shaped and aligned to form the desired heat sink structure. This step is crucial as it ensures that the fins are spaced correctly to maximize airflow and thermal performance.

4. Finishing: The heat sink is polished and finished to remove any burrs or imperfections that could impede its performance. This step also often involves anodizing or coating the heat sink to improve its durability and resistance to environmental factors.

What is the Equipment Used in Skiving Heat Sinks?

The equipment used in skiving heat sinks includes precision skiving machines capable of accurately slicing and shaping metal layers. These machines are designed to handle the high precision required for creating thin, uniform fins that are essential for optimal thermal performance.

Key Components of Skiving Machines

• High-Precision Blades: The blades must be exceptionally sharp and made from durable materials to withstand the repeated slicing of metal.

• Control Systems: Modern skiving machines are equipped with advanced control systems that allow for precise adjustments to blade position and cutting speed.

• Cooling Systems: To prevent overheating and ensure consistent performance, skiving machines often include integrated cooling systems.

• Automation and Software: Many skiving machines are automated and controlled by sophisticated software, allowing for the programming of specific cutting patterns and adjustments based on real-time data.

Maintenance of Skiving Equipment

Regular maintenance is crucial for skiving machines to ensure their longevity and consistent performance. This includes routine sharpening of blades, calibration of control systems, and inspection of cooling mechanisms.

Proper maintenance not only extends the lifespan of the equipment but also ensures the production of high-quality heat sinks.

What Are the Applications of Skiving Heat Sinks?

Skiving heat sinks are used in a variety of applications, including:

• Electronics Cooling: Used in computers, servers, and other electronic devices to manage heat. The high efficiency of skiving heat sinks makes them ideal for densely packed electronic assemblies where space is at a premium.

• Power Modules: Essential for cooling power electronics and inverters, which generate significant amounts of heat during operation. The ability to create custom shapes and sizes allows skiving heat sinks to be tailored to specific power module designs.

• Energy Storage Systems: Help manage the thermal load in batteries and other energy storage solutions. Effective thermal management in energy storage systems is critical for safety and performance.

• Telecommunications: Used in telecom equipment to maintain optimal operating temperatures. As telecommunications equipment becomes more advanced and compact, efficient cooling solutions like skiving heat sinks are increasingly important.

• Electric Vehicles (EVs): Managing the thermal loads in battery packs and power electronics.

• Renewable Energy Systems: Cooling components in solar inverters and wind turbine control systems.

• Medical Devices: Ensuring reliable operation of high-performance medical equipment that generates heat.

What Are the Benefits and Limitations of Skiving Heat Sinks?

• Improved Thermal Performance: The increased surface area provided by the fins enhances heat dissipation. This makes skiving heat sinks highly effective in high-power applications where traditional cooling methods might not suffice.

• Design Flexibility: Skiving allows for the creation of thin fins with high aspect ratios, providing more design options. This flexibility enables the development of custom cooling solutions tailored to specific applications.

• Structural Integrity: Since the fins are an integral part of the base, there is no risk of them detaching. This results in a more durable and reliable heat sink.

• Cost-Effective Production: While the initial setup may be costly, skiving can be more cost-effective for high-volume production runs. The precision of the process ensures minimal material waste and high repeatability.

Despite their benefits, skiving heat sinks have some limitations:

• Material Constraints: Skiving is typically limited to materials like copper and aluminum. These materials, while excellent for thermal conductivity, might not be suitable for all applications.

• Manufacturing Complexity: The precision required for skiving can make the manufacturing process complex and time-consuming. This can result in higher costs and longer lead times compared to simpler manufacturing methods.

• Initial Costs: The cost of precision skiving equipment and setup can be high. This initial investment might be a barrier for small-scale operations or low-volume production runs.

How Much Do Skiving Heat Sinks Cost?

The cost of skiving heat sinks varies based on factors such as material, design complexity, and production volume. Generally, skiving heat sinks are more expensive than simpler designs like extruded heat sinks, but their superior performance can justify the higher cost in demanding applications.

Factors Influencing Cost

• Material Costs: The cost of the raw material (copper or aluminum) significantly impacts the overall cost of the heat sink. Copper, being more expensive than aluminum, will result in higher costs.

• Design Complexity: More complex designs that require intricate skiving patterns or additional machining steps will increase the cost.

• Production Volume: High-volume production runs can reduce the cost per unit due to economies of scale. Conversely, low-volume production might result in higher costs per unit.

• Finishing and Coating: Additional processes like anodizing or coating add to the cost but can enhance the performance and durability of the heat sink.

Cost Comparison with Other Heat Sink Types

Compared to other types of heat sinks, such as extruded or stamped heat sinks, skiving heat sinks tend to be more expensive.

However, their superior thermal performance and design flexibility often justify the higher cost, especially in applications where efficient heat dissipation is critical.

What Kind of Material Can Be Used in Skiving Heat Sinks?

Skiving heat sinks are typically made from:

• Copper: Offers excellent thermal conductivity and is ideal for high-performance applications. Copper skiving heat sinks are highly efficient in heat dissipation and are often used in demanding applications where maximum thermal management is required.

• Aluminum: While not as conductive as copper, aluminum is lighter and less expensive, making it suitable for many applications. Aluminum skiving heat sinks are widely used in consumer electronics, automotive, and telecommunications due to their balance of performance and cost.

Detailed Analysis of Materials

• Copper: Copper has the highest thermal conductivity among commonly used heat sink materials, making it the best choice for applications that require maximum heat dissipation. However, copper is also heavier and more expensive than aluminum.

• Aluminum: Aluminum is the most widely used material for heat sinks due to its good thermal conductivity, low cost, and lightweight. Aluminum can also be anodized to improve its thermal performance and durability.

Summary

Skiving heat sinks offer numerous advantages in thermal management, making them a popular choice in various industries. Understanding their benefits, limitations, and applications can help in selecting the right solution for your needs.

By leveraging the precision and efficiency of the skiving process, engineers and production managers can ensure optimal thermal performance for their electronic devices.

The comprehensive analysis of skiving heat sinks, from their manufacturing process to their applications, highlights their importance in modern thermal management solutions.