Die Casting Services

China Precision Aluminum Die Casting Manufacturer

Get the high-quality parts you need quickly with our all-in-one aluminum die casting expertise.

Typical Lead Time

Tooling = 4 weeks Samples = 1-2 weeks Production (Qty 10k) = Around 3-4 weeks

Cost Effective

Die casting can save money by reducing waste material and scrap.

100% Guarantee

ISO 9001 & ISO 13485 & IATF 16949 certified

Free Estimation

Select from a wide range of materials, finishes, tolerances, markings, and certifications for your order.

What is the Metal Die Casting Process?

Die casting is a metal casting method where molten metal is forced into a mold cavity under high pressure. This technique is used to produce large quantities of small to medium-sized parts with intricate details. The materials commonly used in this process are non-ferrous metals such as aluminum, magnesium, and zinc alloys. The high pressure ensures that the molten metal completely fills the mold cavity and forms the desired shape with great precision.

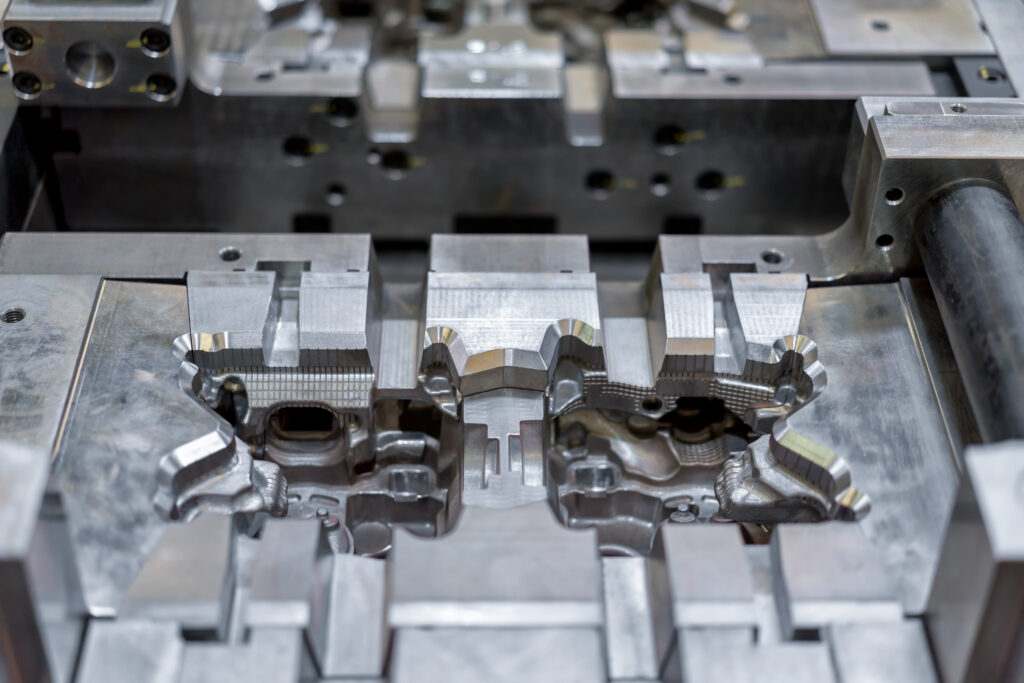

Metal Die Casting Process

The mold, also known as the die, is typically made from hardened tool steel and designed to withstand the high pressures and temperatures involved in the process. The mold is first cleaned and treated to ensure it is free of any impurities that could affect the quality of the final product. A lubricant is then applied to the mold to facilitate the easy removal of the cast part and to prolong the life of the mold by reducing wear.

In this step, molten metal is injected into the mold cavity under high pressure. This pressure is maintained until the metal solidifies. The high pressure ensures that the molten metal reaches all the intricate details of the mold, resulting in a highly accurate and detailed part. The speed of injection is also crucial, as it affects the final product's surface finish and structural integrity.

Once the metal has solidified, the mold is opened, and the cast part is ejected. This step must be carried out carefully to avoid damaging the part. Ejector pins are often used to push the part out of the mold. The mold is then closed and prepared for the next injection cycle.

After ejection, the cast part undergoes a process called shakeout, where any excess material, such as the runners and sprues, is removed. This can be done manually or using automated equipment. The part may also undergo additional finishing processes, such as trimming, sanding, or machining, to achieve the desired specifications.

Die Cast Metal Materials

Metals used in die casting are typically non-ferrous, such as bronze, aluminum, zinc, magnesium, or copper. Alloys, especially steel alloys, can also be used, but steel parts are usually forged instead.

GET YOUR CUSTOM DIE CAST COMPONENTS

When manufacturing with die casting, you can choose from several different metal materials. The material you select will depend on how you plan to use the product.

Available Finishes

Zinc and aluminum-zinc parts can be left as-cast and still resist corrosion. Aluminum parts need to be coated for corrosion resistance. Cast parts are usually separated from the casting sprue, leaving rough marks at the gate locations. Most castings will also have visible marks from the ejector pins. The surface finish for as-cast zinc alloys is usually 16-64 microinch Ra.

You can use sandblasting to peel paint, smooth out rust, take bumps and mars from stuff, and basically make things clean. Ironically, you can also sandblast things to scuff them up by etching the surface and give something a little bit of ‘tooth’ so that paint will stick better.

Type II anodizing enhances corrosion resistance. It allows parts to be colored in various shades like clear, black, red, and gold, typically for aluminum. Type III provides a thicker, wear-resistant layer as well as the corrosion resistance of Type II.

All die-cast parts can be powder coated. In this process, powdered paint is sprayed onto a part using static electricity, then baked in an oven. Powder coating creates a strong, wear- and corrosion-resistant layer that is more durable than regular painting methods. Many colors are available to achieve the desired look.

Die cast parts can be plated with electroless nickel, nickel, brass, tin, chrome, chromate, Teflon, silver and gold.

All die cast parts can be wet painted in a wide variety of paint formulations and colors.

Suppliers can add a chromate conversion coat to protect aluminum from corrosion and help paints and primers stick better. Chemical film conversion coatings are also electrically conductive.

Can't find the finish you require? Send us an RFQ, and we'll explore a finishing solution for you.

Design Guidelines

Before die casting your part, manufacturers will consider several factors, such as element thickness and details (which affect the time the metal spends in the mold) and the complexity of the design (which affects solidification time).

Tolerence

As cast tolerance as tight as +/- .005”, post machining available for tighter tolerance applications.

1

Finish

Typical surface finish of Ra 63 micro-inch as cast, post machining available for higher quality finishes.

2

Wall Thickness

Aluminum minimum wall thickness = .08”

3

Tolerence

Standard tolerance of +/- .005” for the first inch and +/-.002” each additional inch.

4

Draft

Minimum draft = .5 degrees

5

Wall Thickness

Zinc minimum wall thickness = .04”

6

Applications of Metal Die Casting

Electronics Industry

Die-cast parts are commonly used in electronic devices for housings, heat sinks, and connectors. The ability to produce complex shapes with tight tolerances is crucial for the electronics industry.

Industrial Machinery

Die casting is used to produce various components for industrial machinery, including pumps, valves, and gears. The durability and precision of die-cast parts are essential for the reliable operation of industrial equipment.

Automotive Industry

Die casting is used to produce a wide range of automotive components, including engine blocks, transmission housings, and structural parts. The high precision and strength of die-cast parts make them ideal for demanding automotive applications.

Consumer Goods

Many household items and consumer products, such as kitchen appliances, power tools, and decorative hardware, are manufactured using die casting. The process allows for the creation of aesthetically pleasing parts with a high-quality finish.

Die Casting FAQs

Die casting comes in several flavors, each with its own set of advantages and applications:

Hot Chamber Die Casting

In hot chamber die casting, the metal is melted in a chamber that's part of the casting machine. This method is efficient and ideal for metals with low melting points like zinc and magnesium.

Cold Chamber Die Casting

Cold chamber die casting involves melting the metal in a separate furnace and then transferring it to the casting machine. This method is better suited for metals with higher melting points like aluminum and copper.

Gravity Die Casting

Gravity die casting relies on gravity to fill the mold, making it simpler and less expensive than other methods. It's often used for producing large, heavy parts.

Die casting offers numerous benefits, including:

- High Precision: The process produces parts with tight tolerances and smooth surfaces.

- Efficient Production: It's ideal for large production runs due to its speed and repeatability.

- Cost-Effectiveness: Despite the high initial costs, die casting becomes economical for high-volume production.

However, die casting isn't without its drawbacks:

- Initial Costs: The cost of creating molds and setting up the machinery can be high.

- Metal Limitations: Not all metals are suitable for die casting, limiting material choices.

Die casting is used to produce high-quality metal parts with complex shapes, commonly found in automotive, aerospace, and consumer electronics industries.

Common defects include porosity, cold shuts, and misruns, which can be minimized with proper process control and mold design.

we can help

Provide Customized Solutions

Contact Partzcore (sales@partzcore.com) to get a free quote and expert advice on custom metal parts. Our team will provide the right solution for your project.

Tell Us What You Need

Please share your specific needs with us, including drawings, reference images, and your ideas, so we can turn them into reality.

Professional Team

We will analyze your requirements and drawings to provide the optimal solution, along with a detailed quote within 24 hours.

Approve for Mass Production

Upon receiving your approval and deposit, we will proceed with mass production and manage the shipping process.