What Are the Must-Have Components of a Home Security System?

Your home is your sanctuary, where you should feel safe and protected. However, growing safety concerns can often make homeowners feel vulnerable. This is why investing in a robust home security system is crucial. But what features should you prioritize to maximize protection and peace of mind? A reliable home security system includes essential components […]

Can AI Replace Manual CNC Programming?

CNC (Computer Numerical Control) programming has long been the backbone of precision manufacturing. By converting computer models into machine-readable instructions, it ensures that parts are produced with unmatched accuracy. However, with the rise of Artificial Intelligence (AI), a critical question arises: Can AI replace manual CNC programming? As AI continues to reshape industries, manufacturers are […]

How to Improve the Stability of Sensor Housings?

Manufacturers of sensor housings face critical challenges in ensuring stability and durability for various industrial applications. These components must be functional under demanding conditions, including extreme temperatures, vibrations, and environmental stress. Without robust stability solutions, efficiency drops, and maintenance costs rise, impacting overall productivity. Improving the stability of sensor-sensor housings requires optimizing material selection, refining […]

How does the durability of aluminum compare to other materials in sensor components?

Selecting the ideal material for sensor components is crucial for ensuring optimal performance, longevity, and cost-efficiency. Manufacturers, engineers, and businesses must weigh factors such as durability, corrosion resistance, weight, and strength to determine the best fit for their applications. Among various materials, aluminum is one of the most versatile materials in sensor technology, known for […]

What Are the Challenges and Considerations of Replacing Sensor Components with Aluminum?

Using aluminum as a material for sensor components is gaining momentum across various industries. Renowned for its lightweight structure, affordability, and excellent corrosion resistance, aluminum presents manufacturers and engineers with a compelling alternative to traditional materials like steel and copper. Yet, transitioning to aluminum also brings challenges and considerations that demand careful evaluation. When replacing […]

How Does AI Improve the Accuracy of CNC Machining?

In today’s competitive manufacturing landscape, precision is everything. Precision in CNC machining isn’t just about making a perfect part—it’s about delivering reliability, efficiency, and value. A slight deviation in dimensions can lead to defects, wasted materials, and increased costs, particularly in industries where tolerances are tight, and errors are unacceptable. While traditional CNC machining has […]

Can AI Revolutionize Defect Reduction in Machined Parts?

Defects in machined parts remain a persistent issue for manufacturers, leading to higher costs, production delays, and dissatisfied customers. Whether it’s dimensional inaccuracies or surface flaws, traditional quality control methods often fall short due to limitations in precision and consistency. Nowadays, AI has emerged as a transformative solution to this problem. So, can AI really […]

How to Calculate the Weight of Your Metal Project: A Complete Step-by-Step Guide

Every successful metal project starts with precise measurements. Understanding how to calculate your metal’s weight isn’t just a technical skill—it’s a critical factor that can make or break your entire manufacturing process. For beginners, the task of calculating metal weight can seem intimidating. However, by applying basic formulas and understanding key variables like volume and […]

What Makes CNC Turning Indispensable for Modern Manufacturing?

CNC turning stands out as a cornerstone of modern manufacturing, delivering precision and efficiency. This automated machining process produces complex parts by rotating a workpiece while a stationary cutting tool shapes it. It’s especially renowned for crafting components with cylindrical features but is versatile enough to create intricate designs as well. With its unmatched accuracy […]

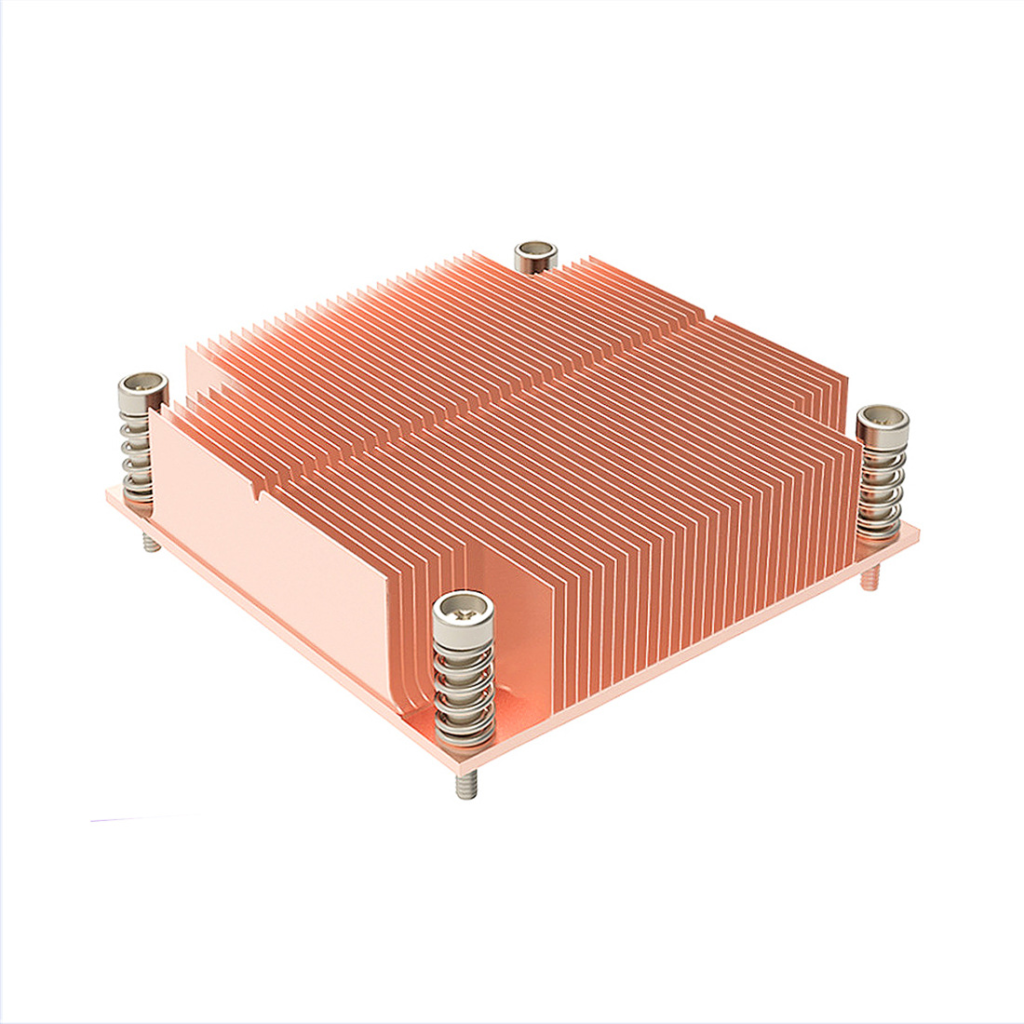

Why Are Copper Skived Heat Sinks the Top Pick for High-Heat Applications?

In industries where managing excessive heat is critical, choosing the right heat sink can make a significant difference in performance and reliability. Copper skived heat sinks stand out as a top-tier solution, offering exceptional thermal conductivity, design flexibility, and durability. Their unique skiving process ensures high efficiency, making them an essential component in applications where […]