Designing efficient heat dissipation solutions is critical to aluminum profile radiators, which are used in various industries, including electronics, automotive, telecommunications, etc.

Without a proper and efficient design, overheating can lead to component failure, reduced lifespan, and increased costs. Understanding the steps involved in designing aluminum profile radiators can help in creating effective thermal management solutions.

Based on the most common design process and our experience, aluminum profile radiator design involves following steps:

- understanding heat dissipation requirements

- selecting appropriate materials

- creating detailed profiles

- maximizing surface area

- simulation and testing

In addition, common challenges are also offered for your reference and attention. Let’s dive deeper into each step to understand how to design aluminum profile radiators with highly efficient heat dissipation.

-

Table Of Contents

-

1. How to Design Aluminum Profile Radiators for Efficient Heat Dissipation?

-

2. Understanding Heat Dissipation Requirements

-

3. Maximizing Surface Area for Better Heat Dissipation

-

4. Simulation and Testing of Radiator Designs

-

5. Common Challenges in Designing Aluminum Profile Radiators

-

6. Summary

Understanding Heat Dissipation Requirements

The first and foremost step is to understand your heat dissipation requirements of the application, which depends on what kind of machines and products the radiators are installed on.

This involves calculating the amount of heat that needs to be dissipated and determining the thermal resistance needed to maintain the desired operating temperature. Precise thermal analysis ensures the radiator meets the system’s cooling needs.

To accurately assess heat dissipation requirements, start by identifying the thermal load generated by the components within the system.

This involves calculating the power consumption of each component and understanding the maximum allowable operating temperature for the system.

Factors such as ambient temperature, airflow conditions, and the presence of other heat-generating components also play a crucial role in determining the heat dissipation needs.

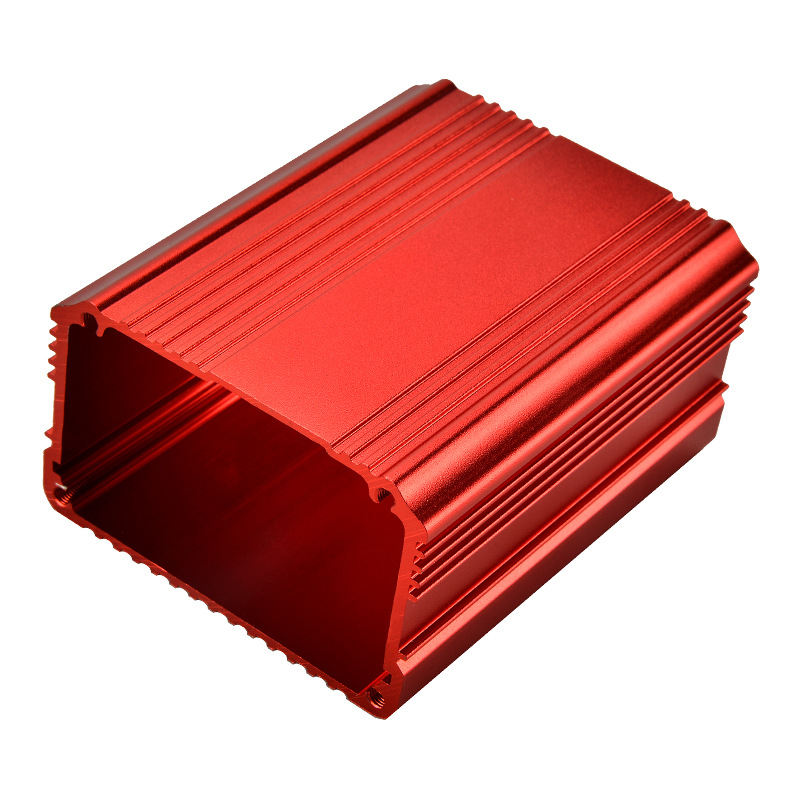

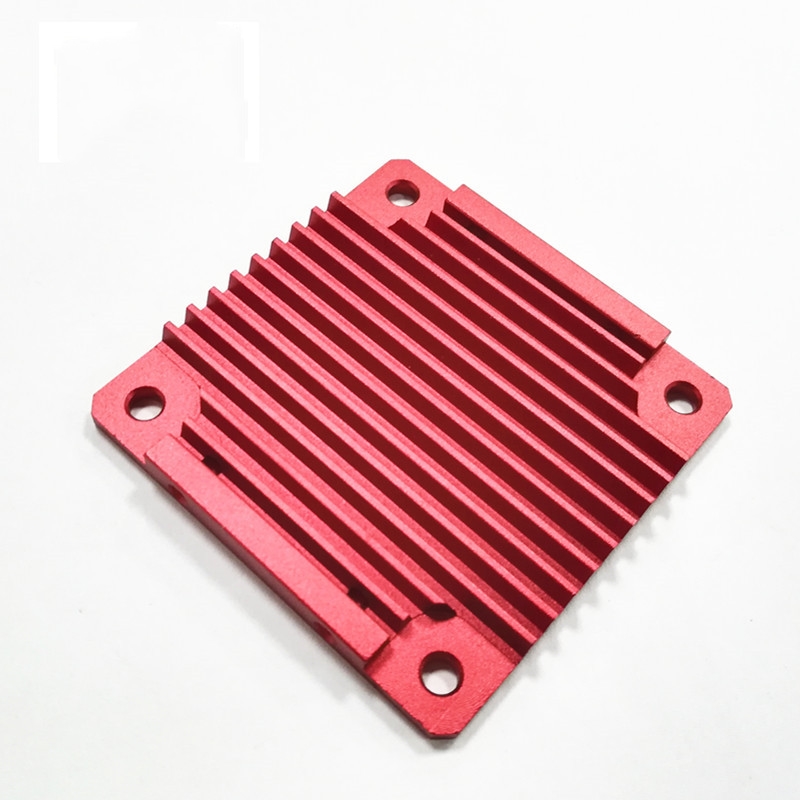

Selecting the Right Aluminum Alloy

Aluminum is featured with many favorable properties in thermal conductivity, weight, corrosion resistance and cost effectiveness. Therefore, choosing the appropriate aluminum alloy is crucial for effective heat dissipation.

Common alloys used in radiator design include 6063 and 6061 due to their excellent thermal conductivity and ease of extrusion. These alloys provide a good balance of strength, formability, and thermal performance.

The choice of alloy should be based on a thorough understanding of the application’s thermal and mechanical requirements. Considerations such as thermal conductivity, strength, corrosion resistance, and cost will influence the selection process.

Anodizing, as a surface treatment, is a necessary process to enhance the performance of aluminum radiators. It produces a marked effect by increasing corrosion resistance and improving emissivity, which prolong the radiator’s lifespan in harsh environments and enhances heat dissipation by increasing the surface’s ability to radiate heat.

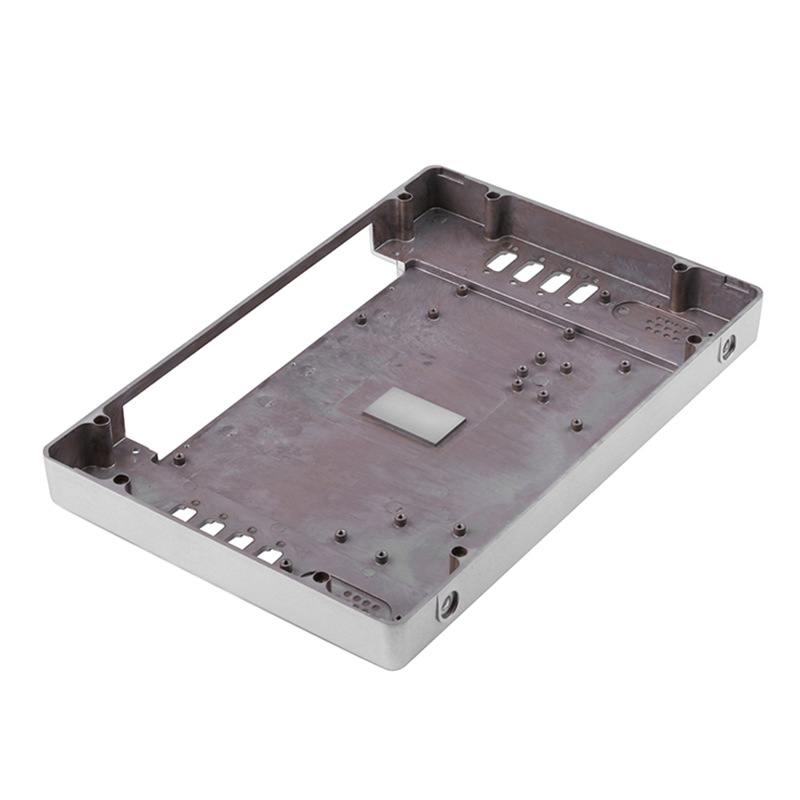

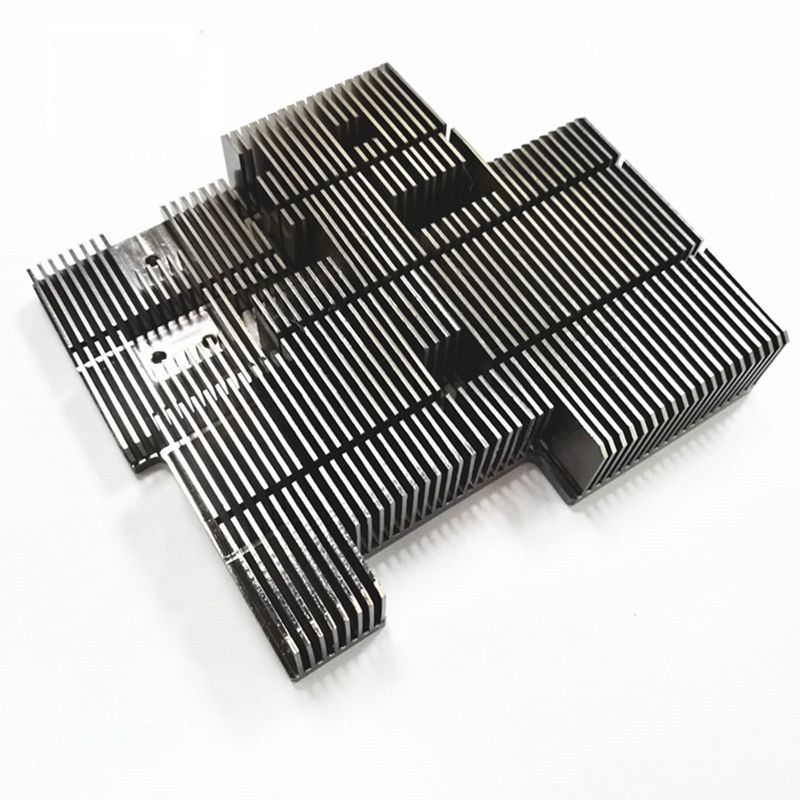

Creating Detailed Profile

Designing detailed profiles involves creating a shape that maximizes the surface area for heat dissipation while fitting within the spatial constraints of the application. This often requires the use of CAD software to draft precise designs.

When creating the profile, consider features that enhance heat dissipation, such as fins, pins, and grooves. Fins, for example, increase the surface area available for heat transfer, improving the radiator’s efficiency.

The geometry of the profile should be designed to facilitate smooth airflow, minimizing resistance and ensuring effective cooling. The design process should also take into account the manufacturability of the profile. Complex shapes may require advanced extrusion techniques and could impact production costs.

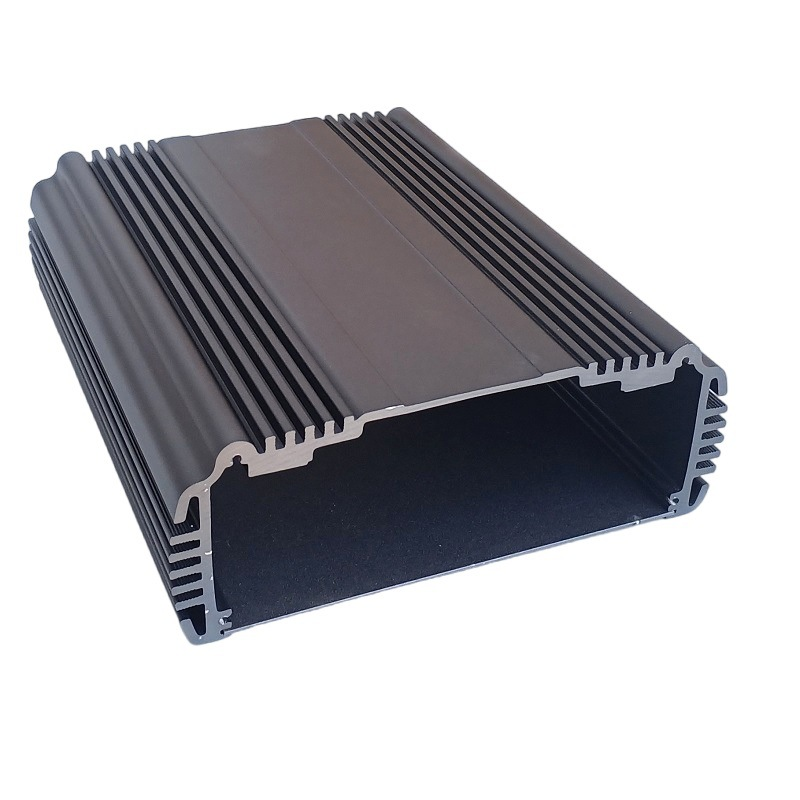

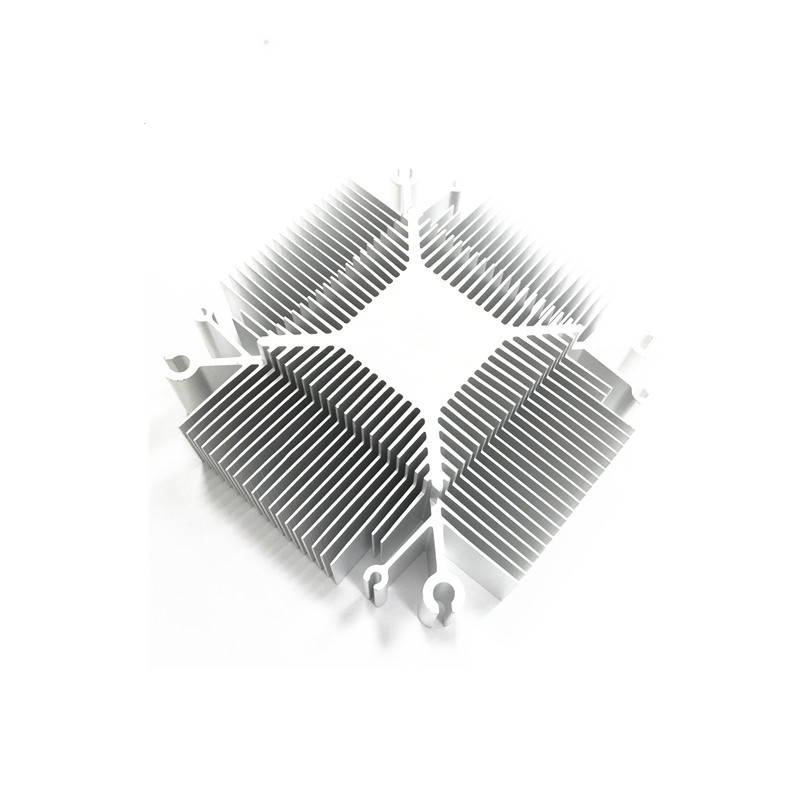

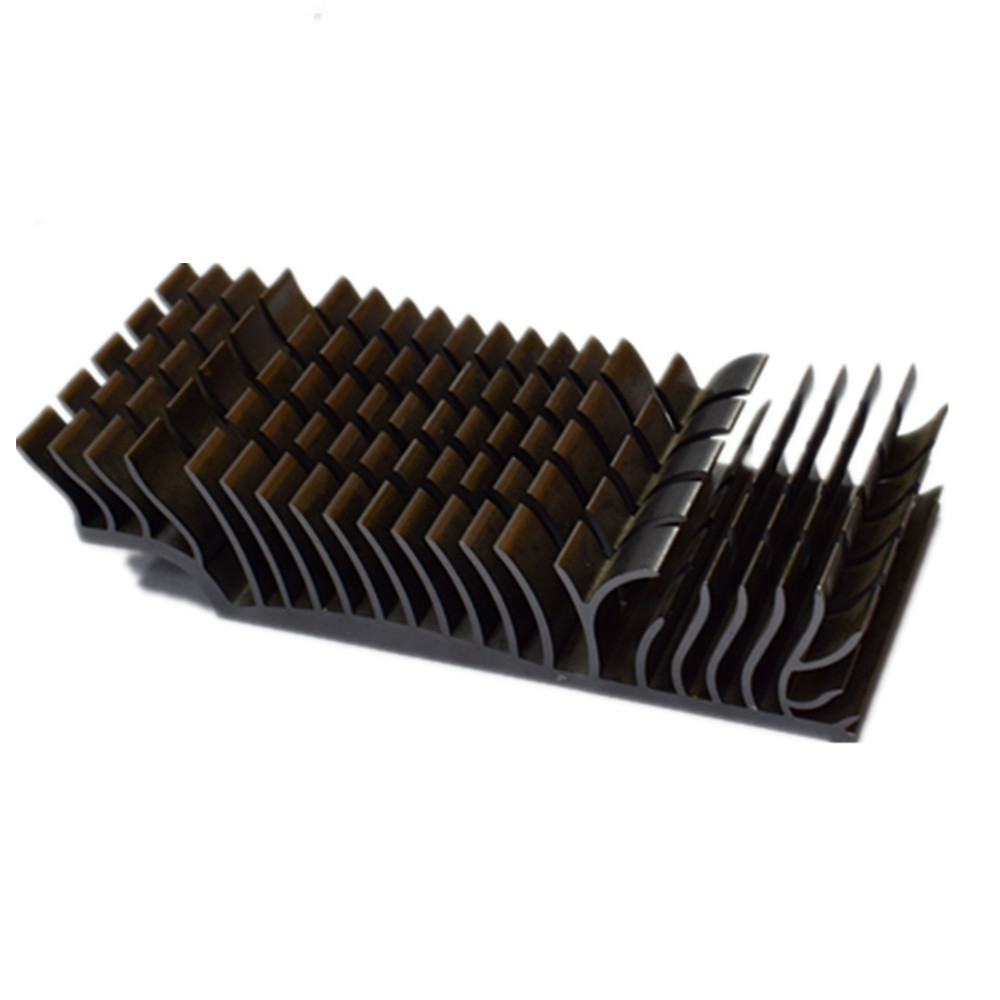

Maximizing Surface Area for Better Heat Dissipation

The efficiency of a radiator is largely dependent on its surface area. Incorporating fins and other features can significantly increase the surface area, enhancing the radiator’s ability to dissipate heat.

The design should aim to maximize the exposed surface area without compromising the structural integrity of the radiator.

To maximize surface area, consider using high-density fin arrays and optimizing the fin geometry. Thin fins with a high aspect ratio can provide a larger surface area for heat transfer while maintaining a compact design.

However, it’s important to balance the fin density with the airflow requirements, as overly dense fin arrays can impede airflow and reduce cooling efficiency. In addition to fins, other features such as pins and microchannels can be incorporated into the design to further increase the surface area.

Simulation and Testing of Radiator Designs

Before finalizing the design, it’s essential to simulate the radiator’s performance under real-world conditions. This can be done using thermal simulation software such as ANSYS or COMSOL, followed by physical testing to validate the results. Simulation and testing help identify potential issues and optimize the design before production.

Once the design is optimized through simulation, physical prototypes should be manufactured and tested to validate the simulation results.

Testing can involve measuring the thermal resistance, heat dissipation capacity, and airflow characteristics of the radiator. Comparing the test results with the simulation data helps ensure the design meets the required performance standards.

Common Challenges in Designing Aluminum Profile Radiators

Some challenges in designing aluminum profile radiators include managing the trade-offs between size, weight, and heat dissipation efficiency, as well as ensuring the radiator can be manufactured within budget. Addressing these challenges requires careful planning and consideration of all design aspects.

One common challenge is balancing the need for high heat dissipation with the constraints of size and weight. Larger radiators with more surface area can dissipate more heat but may not fit within the spatial limitations of the application. Conversely, smaller radiators may be easier to integrate but may not provide sufficient cooling.

Cost considerations also play a significant role in the design process. High-performance materials and complex manufacturing techniques can increase production costs, impacting the overall budget. We must find a balance between performance, manufacturability, and cost to ensure the radiator design is both effective and economically viable.

Summary

Designing aluminum profile radiators requires a meticulous approach to ensure efficient heat dissipation.

Understanding heat dissipation requirements, selecting the right materials, creating detailed profiles, maximizing surface area, and conducting thorough simulations and testing are all crucial steps of the design process.

Addressing common challenges and adhering to best practices can further enhance the performance and reliability of aluminum profile radiators, ensuring they meet the demanding requirements of modern electronic applications.