CNC machining is widely used to manufacture high-precision metal components, but the raw surfaces of these parts often require further treatment to meet specific functional, aesthetic, or durability needs.

This is where surface finishing processes play an essential role.

By applying the appropriate surface finish, manufacturers can improve appearance, enhance corrosion resistance, and optimize overall performance.

Choosing the right surface finish is essential for CNC professionals, engineers, and hobbyists alike.

Common finishing options like anodizing, electroplating, and powder coating each offer unique advantages suited to different applications, enhancing resistance, appearance, or smoothness.

Understanding these options allows you to select the most effective surface finish for your specific project.

This guide will explore the most popular surface finishes used in CNC machining, highlighting their benefits and ideal applications, so you can make the best choice for your metal parts.

-

Table Of Contents

-

1. What Are the Most Common Types of Surface Finishes for Metal CNC Machined Parts?

-

2. What is Surface Finish in Metal CNC Machining?

-

3. Anodizing

-

4. Electroplating

-

5. Powder Coating

-

6. Polishing

-

7. Bead Blasting

-

8. Brushed Finish

-

9. As-Machined Finish

-

10. Electropolishing

-

11. Summary

What is Surface Finish in Metal CNC Machining?

Surface finish refers to the techniques applied to a machined part’s surface to enhance aspects like roughness, texture, and durability.

Surface finishes are often measured by their Ra values (a roughness measurement in micrometers), indicating the surface’s smoothness.

For instance, an “as-machined” finish may have an Ra of around 3.2 μm, showing tool marks, while a polished finish can have an Ra of 0.8 μm or lower for a sleek appearance.

Surface finishes are more than cosmetic—they directly impact a part’s usability. In high-stakes industries like aerospace and medical devices, the right finish can improve corrosion resistance, reduce friction, and increase electrical conductivity.

Selecting the proper finish ensures a component functions optimally in its environment.

1. Anodizing

Anodizing, especially popular for non-ferrous metals like aluminum, enhances parts with a protective oxide layer formed via an electrochemical process.

This finish improves the metal’s resistance to corrosion and wear, and can also add color for aesthetic appeal. Anodizing is a top choice when both appearance and durability are key.

Advantages:

• Enhances corrosion and wear resistance

• Allows coloring options for visual customization

• Provides non-conductive surfaces ideal for electronics

With recent advancements, “hard anodizing” has emerged, providing an even tougher oxide layer.

This technique supports metal parts exposed to extreme environments, enhancing both wear and temperature resistance, especially valuable in sectors like aerospace and marine.

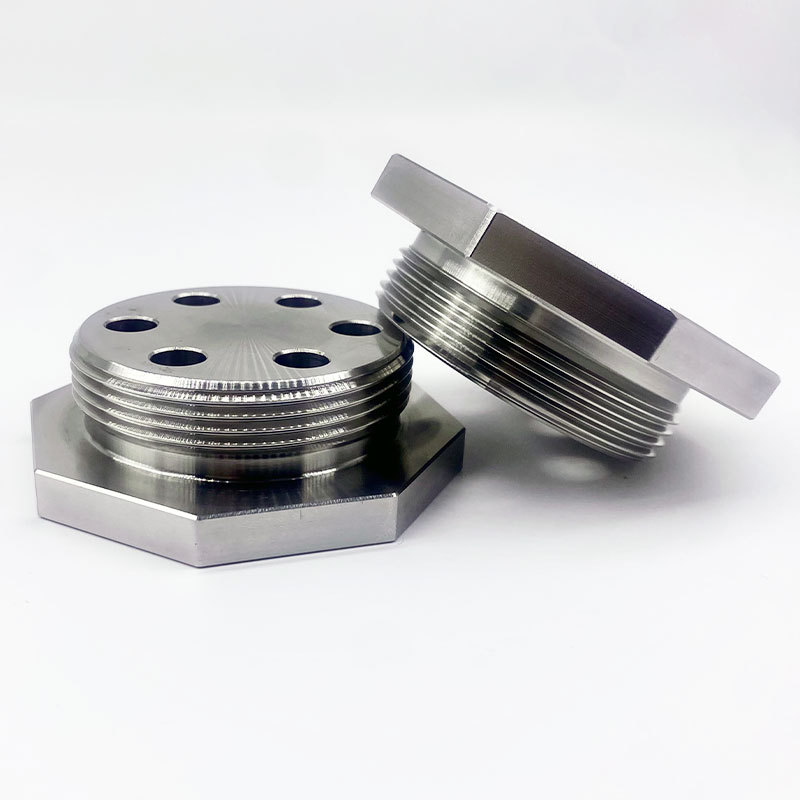

2. Electroplating

Electroplating coats a part’s surface with a thin metal layer—commonly chrome, nickel, or gold.

This finish improves durability, appearance, and corrosion resistance while potentially enhancing conductivity, making it ideal for electronic components.

Electroplating is equally popular for decorative and functional uses.

Advantages:

• Provides decorative finishes with a metallic shine

• Increases corrosion and wear resistance

• Enhances conductivity for electrical applications

The integration of composite materials in electroplating, like nickel-phosphorous or nickel-Teflon coatings, enables parts to achieve superior durability and chemical resistance.

This process has rapidly gained attention in electronics and industrial sectors, as these composites ensure both conductive properties and extended lifespan.

3. Powder Coating

Powder coating involves applying powdered paint that adheres through electrostatic charge and is then cured in an oven.

This technique results in a hard, durable finish with a variety of colors and textures, making it versatile for functional and decorative applications.

Powder coating is chip-resistant and eco-friendly due to minimal volatile organic compound (VOC) emissions.

Advantages:

• Durable, scratch-resistant finish

• Provides vibrant colors and textures

• Eco-friendly process with low emissions

“Functional powder coatings,” such as anti-microbial or anti-static versions, are increasingly common.

These specialized coatings are valuable in healthcare and food processing where hygiene or static control is essential, showcasing how surface finishes can directly address safety and quality demands.

4. Polishing

Polishing creates a high-shine, smooth surface by removing minor imperfections with abrasives or buffing wheels.

This process is ideal for parts needing a clean, low-friction surface, such as in medical tools or automotive components.

Advantages:

• High-gloss, mirror-like surface

• Low friction, ideal for cleanliness in sterile environments

• Aesthetic enhancement for decorative uses

Robotic polishing is increasingly adopted to achieve a consistently smooth surface while maintaining high production efficiency.

By combining robotics with AI, manufacturers can ensure repeatable quality, essential for high-volume industries such as consumer electronics.

5. Bead Blasting

Bead blasting uses high-pressure blasting of tiny glass beads or other abrasives to create a uniform matte finish.

This technique removes surface imperfections and is popular for creating a smooth, non-reflective look. Bead blasting is also an excellent pre-treatment before additional finishes.

Advantages:

• Uniform, matte finish hides tool marks

• Removes contaminants and surface flaws

• Provides a non-reflective appearance

Automated bead blasting systems enable precise, consistent results with less material waste.

Moreover, the use of alternative media, such as organic abrasives, minimizes environmental impact, reflecting a shift toward sustainable manufacturing practices.

6. Brushed Finish

A brushed finish adds a distinctive linear texture to the metal surface, creating a modern matte appearance.

This finish conceals imperfections, making it visually appealing for visible parts. It is a common choice for consumer goods and appliances, where aesthetics are a priority.

Advantages:

• Unique, professional matte appearance

• Conceals minor surface imperfections

• Simple, cost-effective application

In high-end consumer products, automated brushing techniques are used to create intricate patterns, such as cross-hatching or custom designs, which elevate brand identity and add value through visual distinction.

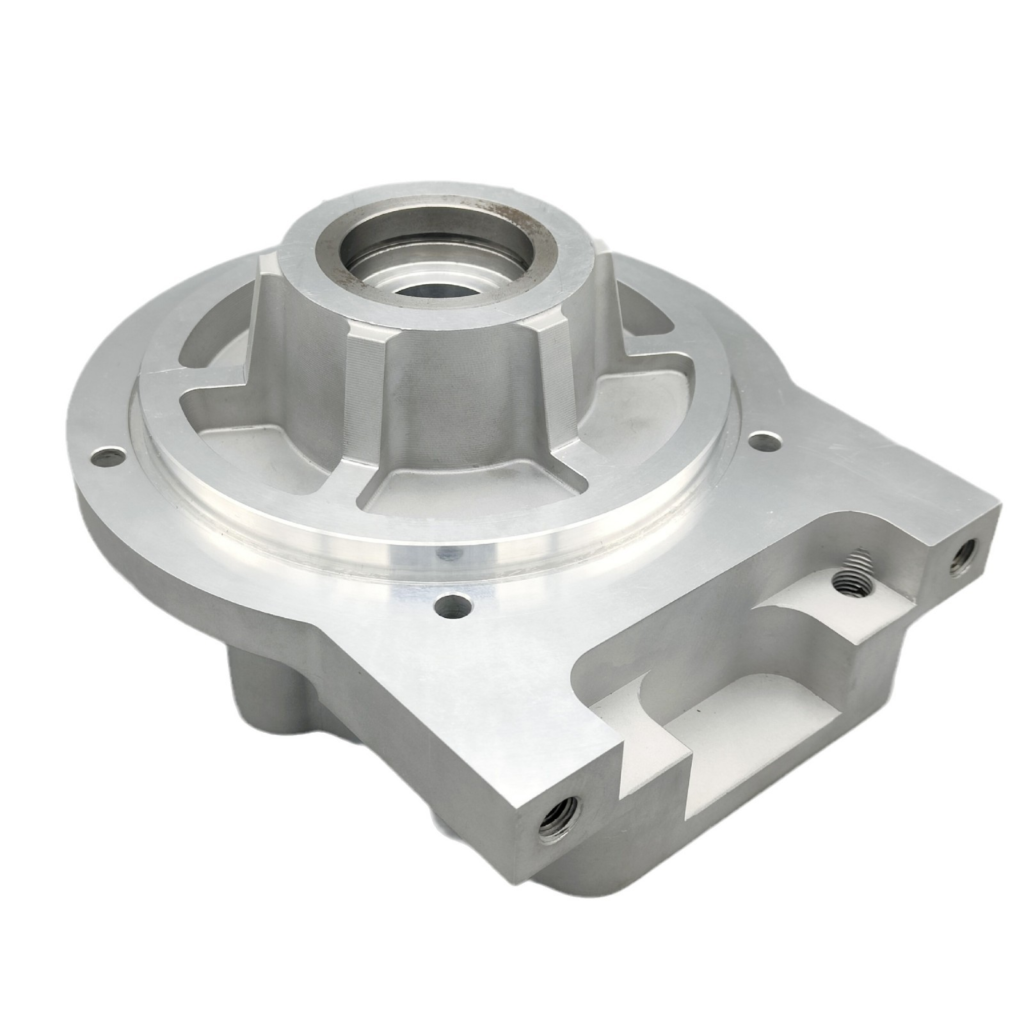

7. As-Machined Finish

The as-machined finish is the result of machining without further treatment, leaving visible tool marks.

This finish is both precise and cost-effective, making it suitable for functional components where aesthetics aren’t a priority.

Advantages:

• No additional finishing steps, reducing costs

• Retains exact dimensions from machining

• Ideal for internal or hidden parts

For precision-critical industries like robotics, leaving parts as-machined while ensuring tighter tolerances offers both cost savings and functionality.

This approach also benefits rapid prototyping, where maintaining exact measurements is essential for fit and function testing.

8. Electropolishing

Electropolishing, a chemical finish that removes a thin surface layer, creates an ultra-smooth, polished appearance.

It’s particularly useful in applications requiring sterility and corrosion resistance, such as medical devices or food processing equipment.

Advantages:

• Smooth, polished surface reduces contamination risk

• Enhances corrosion resistance

• Suitable for sterile, high-hygiene environments

Electropolishing combined with micro-polishing provides an exceptionally smooth finish, minimizing friction further and supporting the growing demand for high-performance medical and scientific instruments.

Summary

Choosing the right surface finish is integral to ensuring the performance, appearance, and durability of metal CNC parts.

From anodizing to electropolishing, each surface finish has unique benefits, serving diverse applications across industries.

In today’s market, where precision, durability, and aesthetic appeal are paramount, integrating innovative finishing options such as composite electroplating or antimicrobial powder coatings can add substantial value to CNC machined parts.

By considering factors such as material, environment, and intended use, manufacturers can leverage the best finishing techniques to ensure optimal functionality and satisfaction.