Extruded aluminum is a powerhouse material that’s revolutionizing multiple industries. Despite its widespread use, many professionals are unaware of its full potential and diverse applications.

Understanding the benefits and types of extruded aluminum can unlock new opportunities for innovation and efficiency in your projects.

Extruded aluminum is widely used in construction, automotive, aerospace, and manufacturing industries due to its versatility, lightweight, strength, and resistance to corrosion.

Common applications include structural components, frames, heat sinks, tracks, rails, and various custom profiles.

In addition to knowing where they are used, now let’s dive deeper into the types, specific uses and benefits of extruded aluminum in various sectors.

What are the Types of Extruded Aluminum?

1. Solid Extrusions

Solid extrusions are continuous profiles without any enclosed voids. These are used for applications requiring high strength and rigidity, such as structural beams and support columns. The solid nature of these extrusions provides maximum load-bearing capacity and durability.

2. Hollow Extrusions

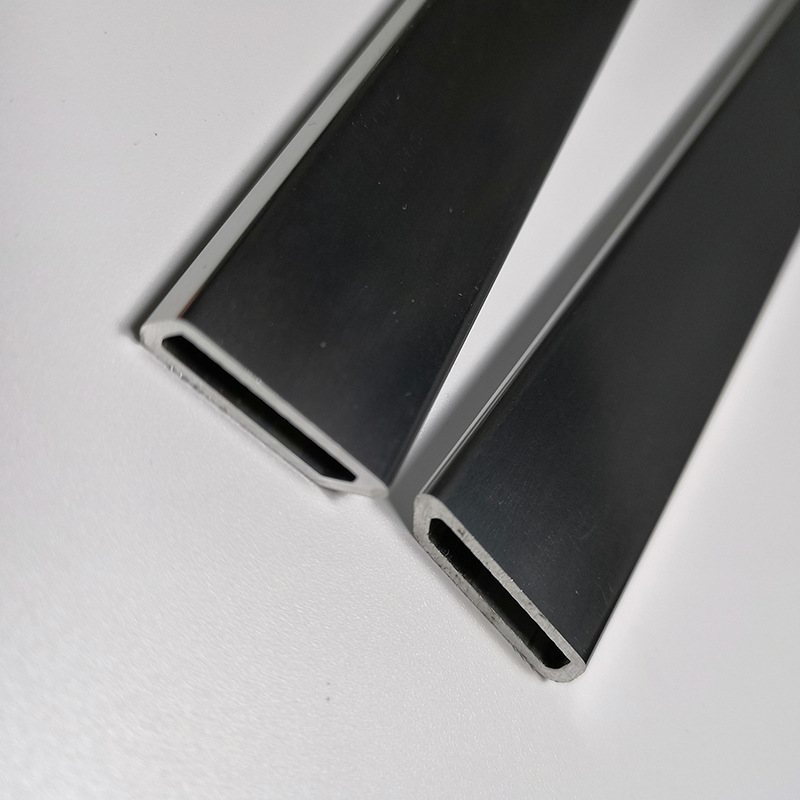

Hollow extrusions have one or more enclosed voids within the profile. These are used in applications where weight reduction is crucial without sacrificing structural integrity. Common uses include tubing, pipes, and complex shapes that require internal cavities for functional purposes.

3. Semi-Hollow Extrusions

Semi-hollow extrusions have partially enclosed voids, offering a balance between the properties of solid and hollow extrusions. These are used in applications that require specific geometric shapes with partial weight reduction. Examples include channels, tracks, and custom profiles for specialized uses.

What are the Applications of Extruded Aluminum?

Construction

Extruded aluminum is extensively used in the construction industry for its strength and lightweight properties.

It’s a key material in creating frames for windows and doors, structural components for buildings, and decorative elements.

The durability and corrosion resistance of aluminum make it ideal for both residential and commercial construction projects.

Moreover, its recyclability adds to its appeal as a sustainable building material. The use of aluminum extrusions in construction not only enhances the structural integrity but also contributes to the aesthetic value of buildings.

Automotive Industry

In the automotive industry, extruded aluminum is prized for its ability to reduce vehicle weight without compromising strength.

This leads to better fuel efficiency and lower emissions. Aluminum extrusions are used in various automotive parts, including engine blocks, chassis, roof rails, and bumper systems.

The adaptability of aluminum allows for custom profiles that meet specific design and performance requirements. Furthermore, aluminum’s excellent corrosion resistance ensures the longevity of automotive components, even under harsh environmental conditions.

Aerospace Sector

The aerospace sector relies heavily on extruded aluminum due to its high strength-to-weight ratio.

This material is used in aircraft structures, including fuselage frames, wing components, and landing gear.

The lightweight nature of aluminum helps improve fuel efficiency and overall performance of aircraft. Additionally, aluminum’s resistance to corrosion ensures long-term durability in the demanding conditions of aerospace environments.

Manufacturing and Machinery

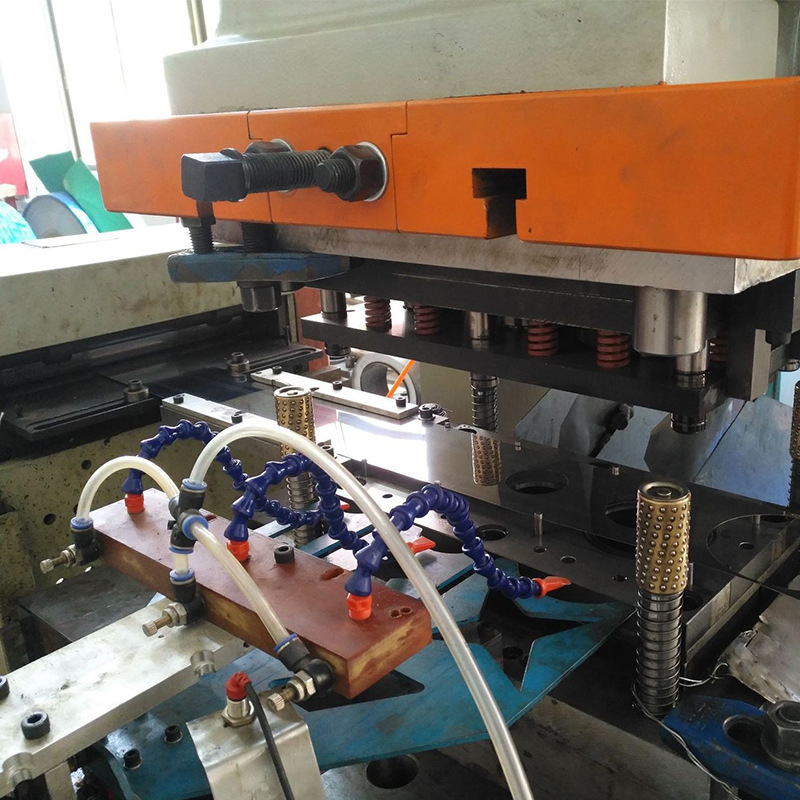

Extruded aluminum profiles are essential in the manufacturing and machinery sectors.

They are used to create machine parts, conveyor systems, and industrial frameworks. The flexibility of aluminum extrusion allows for the production of complex shapes and sizes, meeting the specific needs of various manufacturing processes.

Its excellent machinability and ease of assembly make it a preferred choice for industrial applications.

What Products are Made from Extruded Aluminum?

Frames and Mullions

Extruded aluminum is used to make frames and mullions for windows, doors, and curtain walls. These components provide structural support and enhance the aesthetic appeal of buildings. The strength and lightweight properties of aluminum ensure easy installation and long-term performance.

Heat Sinks

Aluminum extrusions are ideal for manufacturing heat sinks used in electronic devices and industrial machinery. The high thermal conductivity of aluminum allows for efficient heat dissipation, protecting components from overheating and ensuring optimal performance.

Tracks and Rails

Tracks and rails made from extruded aluminum are used in various industries, including transportation, manufacturing, and construction. They provide smooth and reliable movement for sliding doors, conveyor systems, and industrial machinery. The durability and low maintenance requirements of aluminum make it a preferred choice for these applications.

What are the Benefits of Extruded Aluminum?

Lightweight and Strong

One of the primary benefits of extruded aluminum is its excellent strength-to-weight ratio.

Aluminum is significantly lighter than other metals such as steel, yet it offers comparable strength. This makes it an ideal material for applications where weight reduction is crucial, such as in the automotive and aerospace industries.

Corrosion Resistance

Aluminum naturally forms a protective oxide layer on its surface, which enhances its resistance to corrosion.

This makes extruded aluminum suitable for use in environments where exposure to moisture, chemicals, and other corrosive agents is a concern.

The corrosion resistance of aluminum ensures the longevity and performance of components, reducing the need for maintenance and replacement.

Versatility

The extrusion process allows for the creation of complex shapes and profiles with high precision.

This versatility enables the production of components with intricate designs and specific functional requirements.

Aluminum extrusions can be easily customized to meet the unique needs of various applications, making them a preferred choice for designers and engineers.

Recyclability

Aluminum is a highly recyclable material, and extruded aluminum products can be easily recycled without losing their properties.

This makes aluminum extrusion an environmentally friendly choice, contributing to sustainability and reducing the environmental impact of manufacturing processes.

The recycling of aluminum requires significantly less energy compared to the production of primary aluminum, resulting in lower carbon emissions.

Conclusion:

Understanding the diverse applications and benefits of extruded aluminum can significantly impact your project’s success.

Incorporating this versatile material into your designs ensures durability, efficiency, and innovation. For more insights and detailed guidance, explore our additional resources and expert consultations.

By leveraging the unique properties of extruded aluminum, you can enhance the performance and sustainability of your products, meeting the demands of modern industries and contributing to a more sustainable future.