In the world of construction and manufacturing, choosing the right material can make a significant difference in efficiency, cost, and performance.

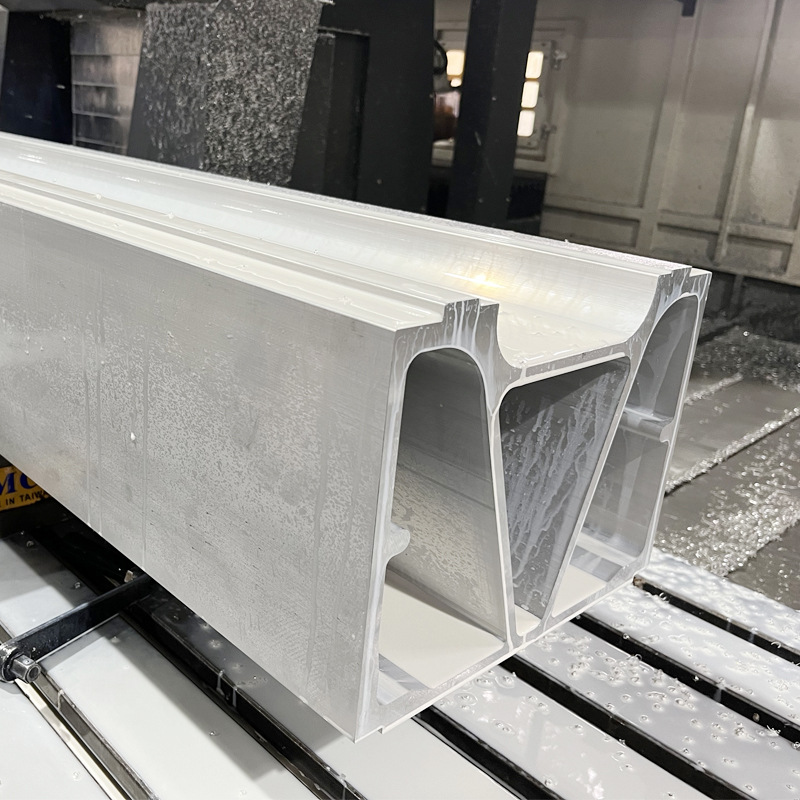

Aluminum profiles have emerged as a versatile and cost-effective solution that addresses many common industry challenges.

Aluminum profiles offer numerous advantages including lightweight, high structural efficiency, corrosion resistance, low maintenance, and cost-effectiveness.

These benefits make them ideal for various industries, particularly construction and architecture, where they are used for window frames, door frames, and structural facades.

Aluminum profiles stand out for their versatility and efficiency, making them a preferred choice in many applications. Next, let’s explore why aluminum profiles are highly regarded and how they compare to other materials.

What Are Aluminum Profiles Used For?

Aluminum profiles are widely used in several sectors due to their unique properties and advantages. In the construction and architecture industry, they are commonly employed for:

• Window frames: Aluminum profiles provide excellent strength and durability while allowing for slim, aesthetic designs.

• Door frames: They offer the same benefits as window frames and are particularly valued for their lightweight and ease of installation.

• Curtain wall systems: Aluminum’s strength-to-weight ratio makes it ideal for curtain walls, which need to support significant loads without adding much weight.

• Structural facades: The ability to withstand environmental stresses and corrosion makes aluminum profiles perfect for structural facades in buildings.

Beyond construction, aluminum profiles find applications in various other industries:

• Automotive Industry: Aluminum profiles are used extensively in the automotive sector for manufacturing vehicle frames, engine components, and body parts. The lightweight nature of aluminum helps in improving fuel efficiency and reducing emissions.

• Aerospace Industry: In aerospace, aluminum profiles are crucial due to their high strength-to-weight ratio, which is essential for aircraft structures. They are used in fuselage frames, wing structures, and other critical components.

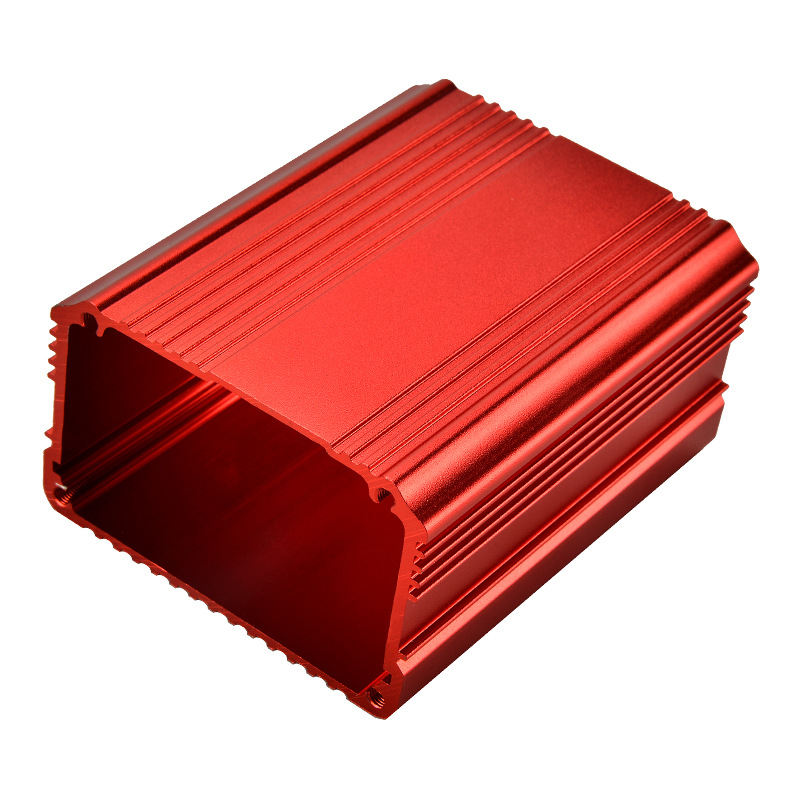

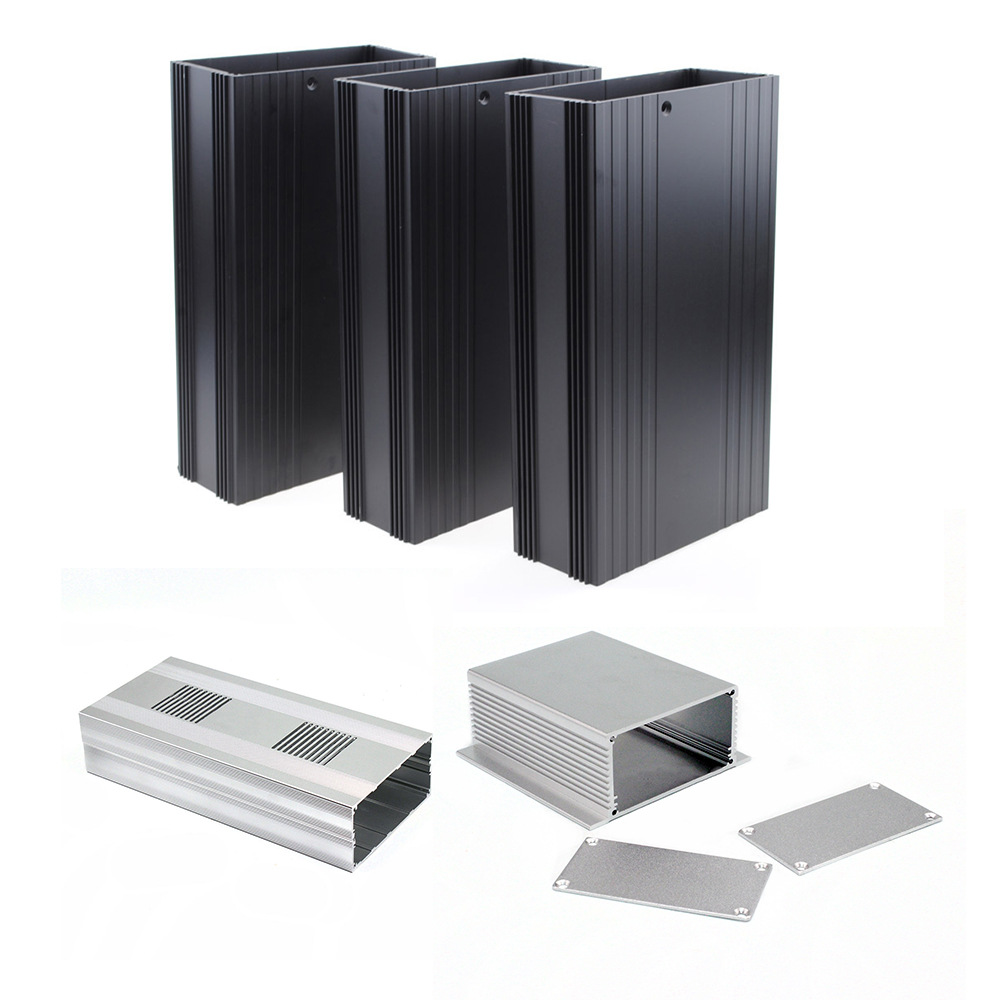

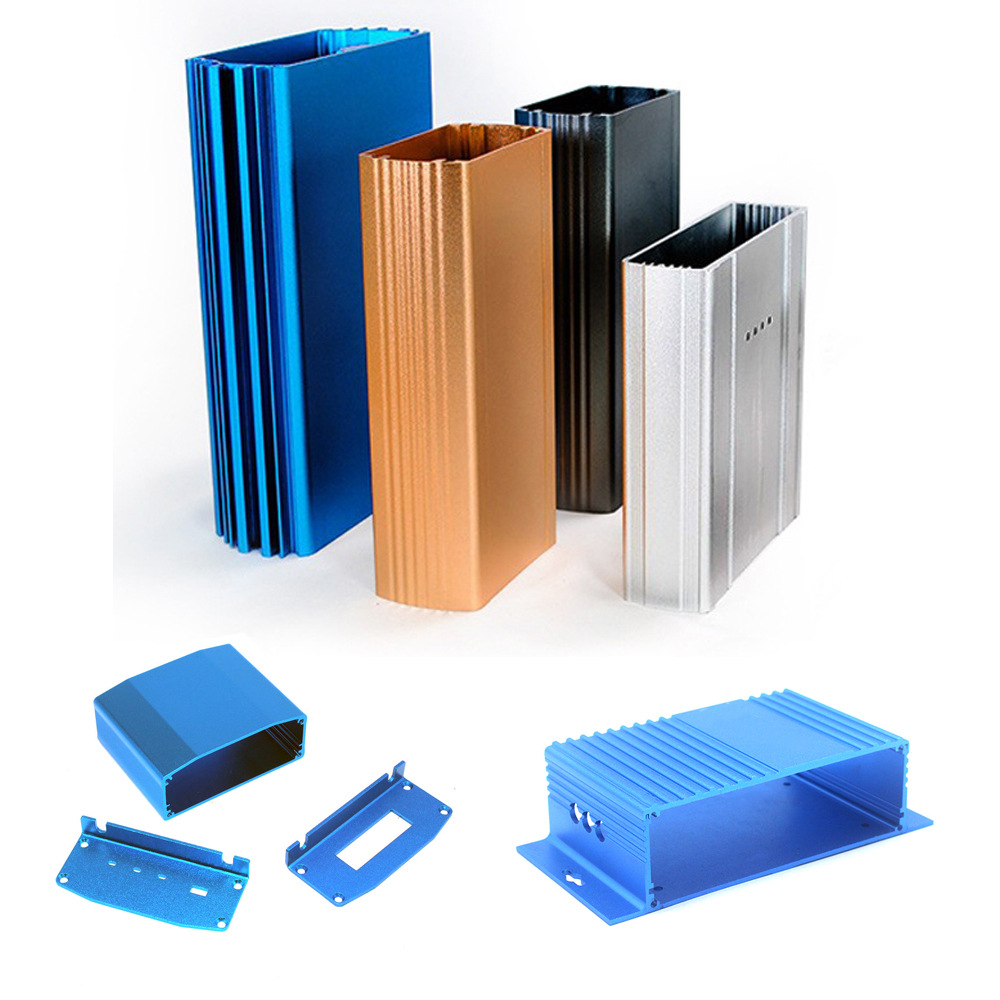

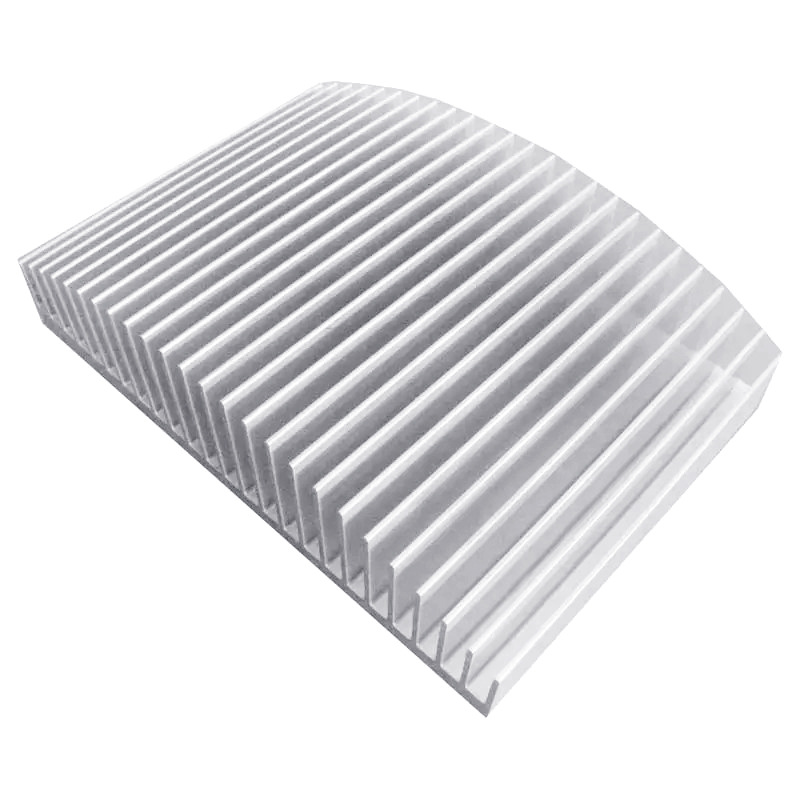

• Electronics Industry: Aluminum profiles are employed in the electronics industry for heat sinks, casings, and enclosures due to their excellent thermal conductivity and ability to dissipate heat efficiently.

• Renewable Energy Sector: Aluminum profiles play a significant role in the renewable energy sector, particularly in the construction of solar panel frames and wind turbine components. Their corrosion resistance and durability are key advantages in these applications.

What are the Advantages of Aluminum Profile?

Aluminum profiles are known for several key advantages:

• High Specific Strength: Aluminum offers a high strength-to-weight ratio, making it ideal for applications where reducing weight is crucial without compromising strength.

• Good Electrical and Thermal Conductivity: Aluminum is an excellent conductor, which is why it’s used in electrical and thermal applications.

• High Reflection Properties: Its ability to reflect light and heat makes it useful in lighting fixtures and heat shields.

• Malleability and Machinability: Aluminum is highly malleable, allowing it to be extruded into complex shapes and profiles. Its machinability means it can be easily cut, drilled, and shaped, reducing manufacturing time and costs.

• Non-Toxic and Non-Combustible: Aluminum is non-toxic and non-combustible, making it safe for use in a wide range of applications, including food and medical industries.

• Aesthetic Versatility: Aluminum can be anodized, painted, or powder-coated to achieve various finishes, enhancing its aesthetic appeal for architectural and consumer applications.

• Cost-effectiveness: While the initial cost of aluminum can be higher than some other materials, its long-term benefits often result in overall cost savings. Factors such as reduced maintenance, longer lifespan, and energy savings (due to lighter weight) contribute to aluminum’s cost-effectiveness.

Comparison with Other Materials

Aluminum vs. Steel

• Weight: Aluminum is about one-third the weight of steel, which makes it easier to handle and reduces transportation costs.

• Corrosion Resistance: Aluminum naturally resists corrosion, while steel often requires additional treatments.

• Strength: While steel is generally stronger, aluminum’s high strength-to-weight ratio makes it suitable for many structural applications.

• Machinability: Aluminum is easier to machine and shape compared to steel, leading to lower manufacturing costs and shorter production times.

• Thermal Conductivity: Aluminum has better thermal conductivity than steel, making it ideal for applications requiring efficient heat dissipation.

Aluminum vs. Wood

• Durability: Aluminum does not warp, rot, or require frequent maintenance, unlike wood.

• Sustainability: Aluminum is more environmentally friendly due to its recyclability, whereas wood often involves deforestation.

• Fire Resistance: Aluminum is non-combustible, providing better fire resistance compared to wood.

• Dimensional Stability: Aluminum maintains its shape and size over time, unlike wood which can expand and contract with changes in humidity.

Aluminum vs. Plastic

• Strength: Aluminum is significantly stronger and more durable than most plastics.

• Temperature Resistance: Aluminum can withstand higher temperatures without deforming, which is a limitation for many plastics.

• Environmental Impact: Aluminum is more eco-friendly as it is fully recyclable, whereas many plastics are not biodegradable and contribute to pollution.

• UV Resistance: Aluminum is resistant to UV radiation, whereas plastics can degrade and become brittle when exposed to sunlight.

Innovations and Future Trends in Aluminum Profiles

The use of aluminum profiles continues to evolve with technological advancements and innovative applications. Here are some future trends to watch:

• 3D Printing with Aluminum: Advances in additive manufacturing are enabling the creation of complex aluminum structures that were previously impossible with traditional methods.

• Improved Alloys: Research and development are leading to the creation of new aluminum alloys with enhanced properties, such as increased strength and corrosion resistance.

• Smart Aluminum Structures: Integration of smart technologies, such as sensors and IoT devices, into aluminum structures for real-time monitoring and maintenance.

• Sustainability Initiatives: Continued focus on sustainability will drive the development of more efficient recycling processes and the use of renewable energy in aluminum production.

• Lightweighting: Ongoing efforts in industries like automotive and aerospace to reduce weight and improve fuel efficiency will further increase the demand for aluminum profiles.

Summary:

In conclusion, aluminum profiles offer a combination of lightweight, strength, and versatility, making them a preferred choice across various industries.

Their advantages include high structural efficiency, corrosion resistance, low maintenance, and cost-effectiveness. Whether for construction, automotive, aerospace, or consumer goods, aluminum profiles provide a reliable and sustainable solution for modern engineering challenges.

With ongoing innovations and a strong focus on sustainability, the future of aluminum profiles looks bright, promising even greater benefits and applications in the years to come.