Choosing the correct type of steel is crucial to product manufacturing. The decision between alloy steel and stainless steel can significantly impact your projects’ quality, durability, and cost. Understanding their differences and benefits will help you make an informed choice.

Generally, alloy steel and stainless steel differ primarily in their resistance to corrosion, strength, and cost. Alloy steel is less corrosion-resistant and requires a protective finish.

In contrast, stainless steel is highly resistant to rust and discolouration, making it suitable for various applications.

If you want a more detailed understanding of the differences between these two materials to make a better choice, let’s delve deeper into the characteristics, advantages, and expected uses of alloy steel and stainless steel.

Alloy Steel Overview

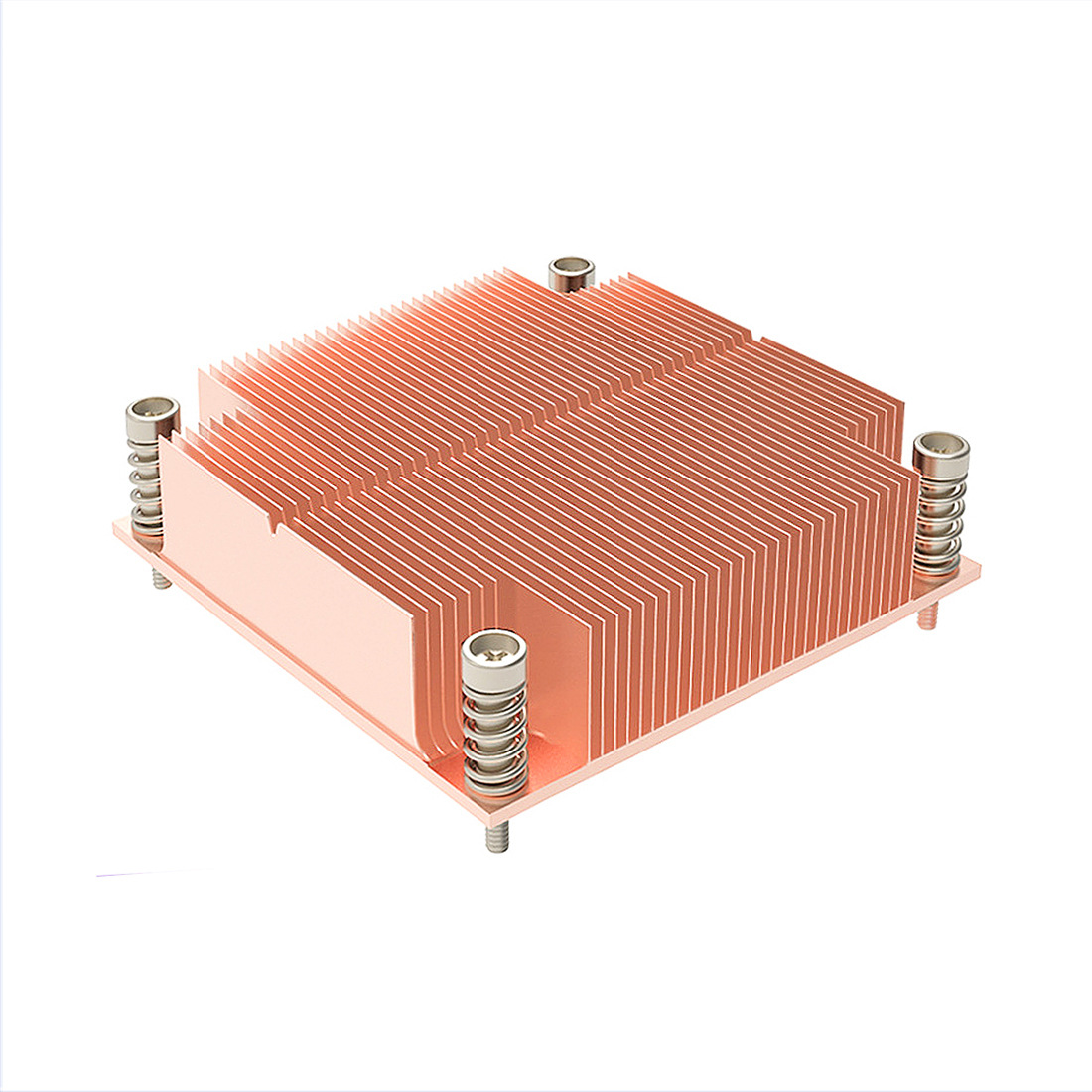

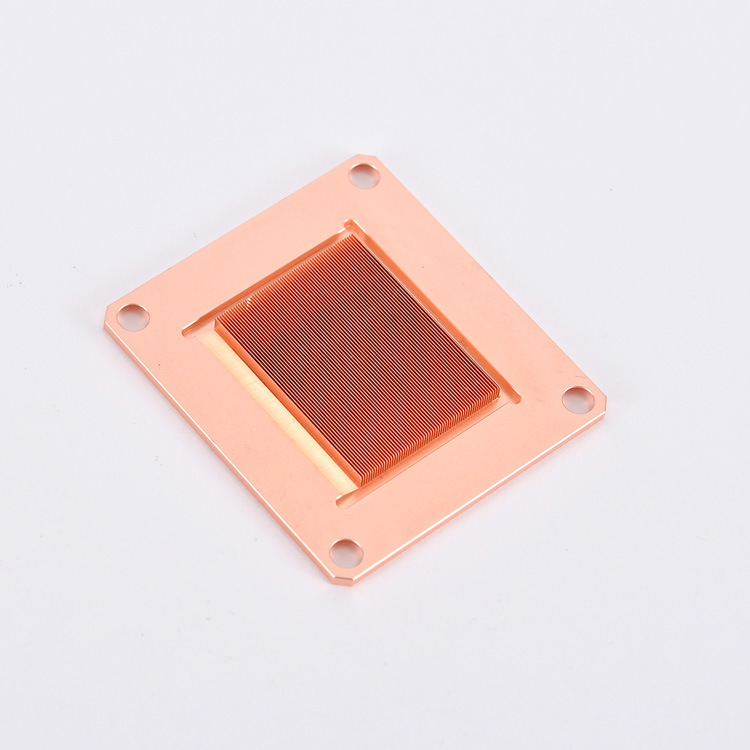

Alloy steel is a versatile material that combines steel with various alloying elements to enhance its mechanical properties. Each component contributes to the overall performance of the steel, making it suitable for a wide range of applications.

Key Properties

Strength: Alloy steel is known for its high strength and ability to withstand heavy loads.

Hardness: Adding elements like vanadium and molybdenum increases the hardness of alloy steel.

Toughness: Alloy steel is tough and can absorb energy without fracturing, making it ideal for impact-resistant applications.

Wear Resistance: The presence of elements like chromium enhances the wear resistance of alloy steel, making it suitable for high-wear environments.

Common Types of Alloy Steel

Alloy steel can be categorized into two main types: low and high alloy.

Alloy Steel contains a relatively small percentage of alloying elements, typically less than 5% by weight. Despite the lower alloy content, these steels offer improved mechanical properties compared to carbon steel.

High Alloy Steel contains more alloying elements, typically more than 5% by weight. These steels exhibit superior mechanical properties and are used in demanding applications.

Advantages of Alloy Steel over Stainless Steel

While alloy steel and stainless steel have unique benefits, alloy steel offers several advantages over stainless steel in specific applications.

Cost-Effective

Alloy steel is generally more affordable than stainless steel, making it a cost-effective choice for many projects. The lower cost is due to the reduced need for expensive alloying elements like chromium and nickel.

Customizability

Alloy steel can be customized to achieve a wide range of mechanical properties. By adjusting the types and amounts of alloying elements, manufacturers can create steel with specific characteristics tailored to the needs of different applications.

High Strength

Alloy steel provides superior strength and hardness, making it ideal for heavy-duty applications. Adding elements like chromium and molybdenum enhances the steel’s ability to withstand high stress and heavy loads.

Wear Resistance

The presence of alloying elements like chromium and vanadium increases the wear resistance of alloy steel. This makes it suitable for applications where the steel is exposed to abrasive forces and high friction.

Versatility

Alloy steel is versatile and can be used in various industries, including construction, automotive, aerospace, oil and gas, and tool manufacturing. Its ability to withstand extreme conditions and heavy loads makes it a preferred choice for demanding applications.

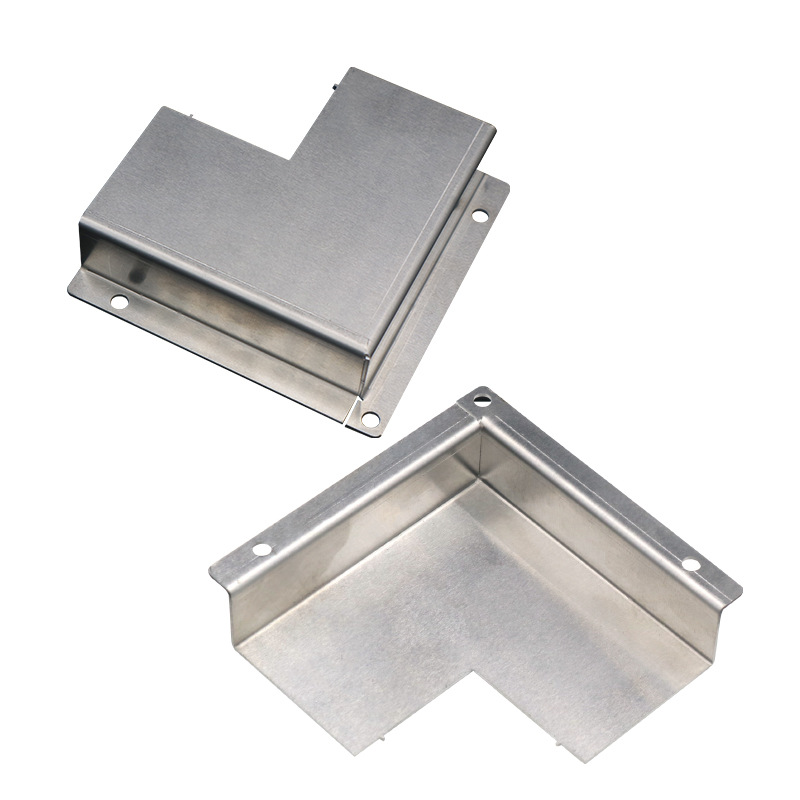

Stainless Steel Overview

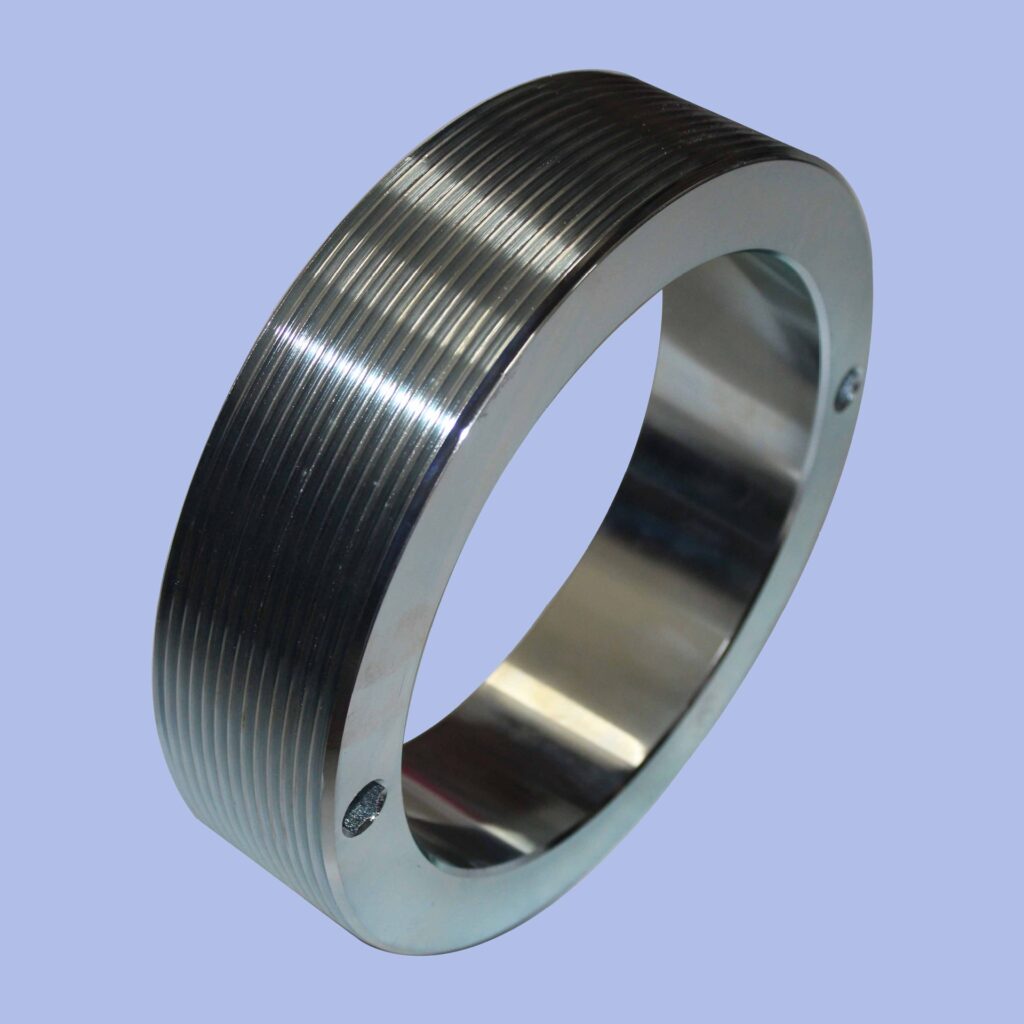

Stainless steel is a type of steel that contains a minimum of 10.5% chromium, which gives it its remarkable corrosion resistance.

The addition of chromium forms a thin layer of chromium oxide on the steel’s surface, protecting it from rust and corrosion. Stainless steel is also known for its durability, aesthetic appeal, and low maintenance requirements.

Key Properties

Corrosion Resistance: Stainless steel is highly resistant to rust and corrosion, making it suitable for harsh environments.

Durability: Stainless steel is solid and durable, capable of withstanding high stress and heavy loads.

Aesthetic Appeal: Stainless steel has a shiny, attractive appearance, making it popular in architectural and decorative applications.

Low Maintenance: Stainless steel requires little to no maintenance due to its corrosion resistance and durability.

Common Types of Stainless Steel

Stainless steel is categorized into several types based on its microstructure and composition. The most common types are austenitic, ferritic, martensitic, and duplex stainless steel.

Austenitic Stainless Steel is the most widely used type of stainless steel. It contains high levels of chromium and nickel, making it highly corrosion-resistant and non-magnetic.

Ferritic Stainless Steel contains high levels of chromium but little or no nickel. It is magnetic and offers good corrosion resistance and formability.

Martensitic Stainless Steel contains chromium and can be heat treated to achieve high hardness and strength. It is magnetic and offers moderate corrosion resistance.

Duplex Stainless Steel is a combination of austenitic and ferritic stainless steel. It offers higher strength and resistance to stress corrosion cracking.

Advantages of Stainless Steel Over Alloy Steel

While alloy steel has advantages, stainless steel offers unique benefits that make it the preferred choice in many applications.

Corrosion Resistance

Stainless steel is highly resistant to rust and corrosion, making it ideal for use in harsh environments. The chromium content forms a protective oxide layer on the surface, preventing the steel from corroding.

Aesthetic Appeal

Stainless steel has a shiny, polished appearance that is visually appealing. It is often used in architectural and decorative applications where aesthetics are essential.

Low Maintenance

Stainless steel requires little maintenance due to its corrosion resistance and durability. It does not need protective coatings or frequent upkeep, making it a cost-effective choice in the long run.

Durability

Stainless steel is solid and durable, capable of withstanding high stress and heavy loads. It is used in applications where long-term performance and reliability are essential.

Hygienic Properties

Stainless steel is easy to clean and does not harbor bacteria, making it ideal for use in the food and beverage, medical, and pharmaceutical industries.

Summary:

Choosing between alloy steel and stainless steel depends on your specific needs and application. Alloy steel offers superior strength and cost-effectiveness, while stainless steel provides unmatched corrosion resistance and low maintenance. Consider your project’s requirements and environment to make the best choice.